-

-

-

-

Technical Services

-

Video picture

22

2025

-

02

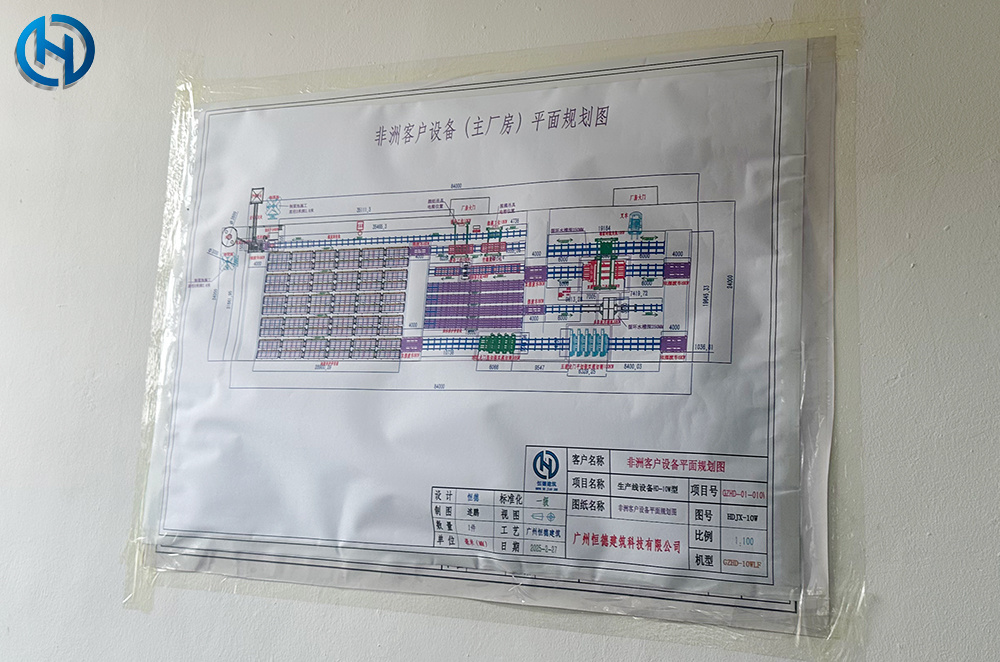

A customer from Ghana, Africa, ordered a set of environmentally friendly block making equipment production line from Guangzhou Hengde.

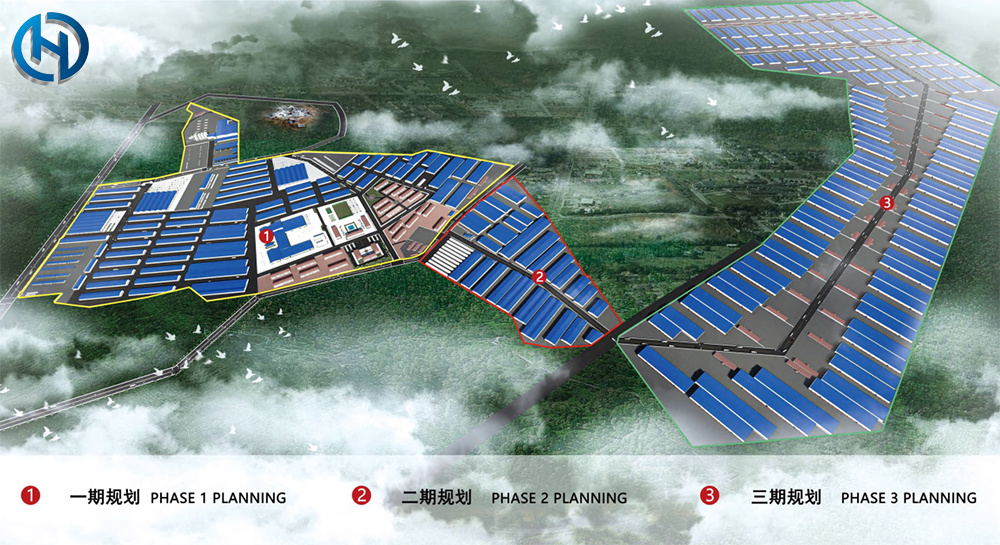

This collaboration involves a large Ghanaian foreign investment group partnering with the Ghanaian government to establish a West African International Free Trade Zone at Tema, the country's largest port. Spanning 7000 mu (approximately 467 hectares), the project will be constructed in three phases, with the first phase exceeding 500 million in investment. Supported by China's Belt and Road Initiative, this collaboration with Guangzhou Hengde introduces an advanced, environmentally friendly building block production line to the local green building materials market, contributing to the region's sustainable development.

The Ghanaian government prioritizes sustainable infrastructure development, mandating that new projects meet low-carbon standards, thus driving the demand for environmentally friendly building materials. The country's building materials market currently relies primarily on traditional materials, resulting in a significant technological gap in advanced, eco-friendly equipment. Lightweight, eco-friendly building blocks, known for their environmental friendliness, insulation, and heat retention properties, are widely used in African construction. They are suitable for residential, educational, and healthcare facilities, as well as for infrastructure projects such as walls and dams.

This collaborative project aligns with the country's national development strategy and leverages the free trade zone platform to achieve regional market coverage, demonstrating strong commercial viability and social benefits.

Why did the Ghanaian client choose Guangzhou Hengde after comparing over 10 equipment suppliers? It comes down to three core advantages:

1. German Technological Background: Introducing the latest generation of CLC foam concrete technology from Germany's LUKAS, with exclusive Chinese distribution rights. The Hengde team has conducted raw material adaptation experiments tailored to Ghana's waste material characteristics, successfully incorporating various tailings into various lightweight bricks. Production line scraps can be recycled, achieving zero emissions and meeting Ghanaian government environmental subsidy requirements.

2. Unrivaled Cutting Technology: Fully CNC controlled, the cutting tolerance for various lightweight block sizes is approximately 1mm, significantly exceeding the highest level in the industry. Cutting dimensions are adjustable, allowing for the production of blocks in any size.

3. Multifunctional Integration: Versatile equipment capable of producing various types of lightweight blocks, self-insulating blocks, ceramsite blocks, waterproof blocks, high-precision blocks, and various new types of lightweight wall panels.

No.25, Fulian Road, Fu'an Industrial Zone, Foshan City

No. 7, Jianyi Road, Xinjiang Wujiaqu Industrial Zone, Bingtuan New Building Materials Industrial Park

12 Potsdam Avenue, Berlin, Germany

WeChat Public Number

TikTok

Copyright©2014-2025 Guangzhou Hengde building materials Co. Ltd.