-

-

-

-

Technical Services

-

Video picture

12

2025

-

05

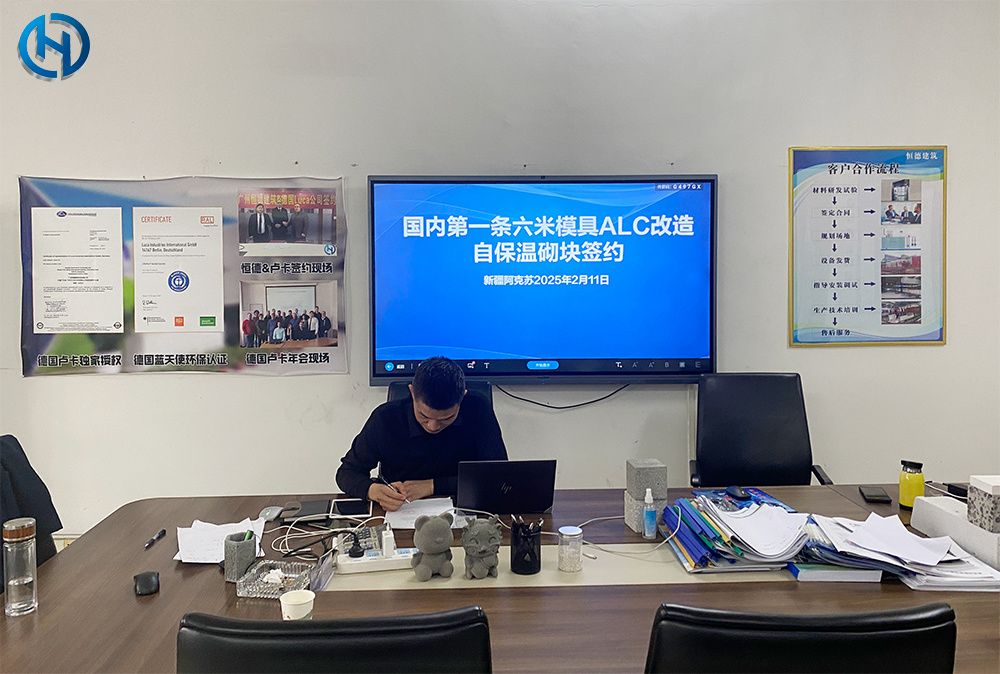

Xinjiang 6-meter mold autoclaved aerated block production line renovation self-insulation block project

In recent years, customers in Aksu, Xinjiang have faced a severe shrinkage in the traditional autoclaved aerated concrete brick market, with product prices continuously declining. Ordinary aerated bricks have lost their competitiveness, and corporate profits have worsened. Against this backdrop, the customer decided to carry out factory renovation and project production transformation. After contacting and investigating multiple domestic companies, they ultimately chose Guangzhou Hengde's customized 6-meter mold production line for homogeneous self-insulating block renovation, the first 6-meter autoclaved aerated block production line renovation project in China, aiming to achieve product transformation through technological upgrades and break through the market dilemma.

The renovation plan integrates German CLC non-autoclaved technology, uses industrial solid waste resource formulas, reducing energy consumption while improving product insulation performance and compressive strength, meeting the building energy-saving standards of the severe cold region in Xinjiang. The production line supports the manufacture of homogeneous self-insulating blocks, lightweight partition boards, and other high value-added products, avoiding low-price competition with traditional aerated bricks and aligning with green building policy directions.

After the equipment arrived at the customer's site, the company's technical team simultaneously started installation and commissioning work, installing without modifying the customer's original production line to ensure the smooth commissioning and production of the renovated production line.

1. Cooperation Signing

2. Equipment Shipment

3. Equipment Installation

4. Production Commissioning

No.25, Fulian Road, Fu'an Industrial Zone, Foshan City

No. 7, Jianyi Road, Xinjiang Wujiaqu Industrial Zone, Bingtuan New Building Materials Industrial Park

12 Potsdam Avenue, Berlin, Germany

WeChat Public Number

TikTok

Copyright©2014-2025 Guangzhou Hengde building materials Co. Ltd.