-

-

-

-

Technical Services

-

Video picture

30

2025

-

06

Xinjiang Tacheng customer self-insulation block equipment production line renovation

Recently, a customer in Tacheng, Xinjiang, chose a set of automated block cutting machines from Guangzhou Hengde for factory renovation and upgrade to a self-insulating block production project, introduced through local old customers and production site cases. The original old equipment has stopped production, and the output and quality cannot be guaranteed.

Main issues with the customer's old vertical cutting machine process:

Insufficient cutting accuracy: The old equipment has large dimensional errors in cutting, resulting in a low finished product pass rate, mainly due to mechanical design defects and component wear, such as poor stability of the cutting saw blade or insufficient pressure in the fixture cylinder causing deviation.

Frequent saw blade breakage: The vertical cutting machine is prone to blade breakage due to poor blade material quality, improper maintenance, or unreasonable cutting parameters (such as excessive speed), increasing downtime and replacement costs.

High labor costs in production: Many operations in the entire production process require a large amount of manual labor, with chaotic workstation layout, long material handling and waiting times, dragging down overall efficiency.

In response to the customer's old equipment production halt pain points, Hengde's solution has the following advantages:

Guangzhou Hengde provided an automated block cutting machine upgrade solution for the Tacheng, Xinjiang customer, which can significantly improve the efficiency and quality of self-insulating block production. This cutting system uses German imported CLC technology and equipment, equipped with a high-precision high-speed cutting saw, cutting accuracy less than 1mm, supports multiple size specifications, has low waste rate, and is easy to maintain. The equipment integrates fully automatic CNC operation and self-heating circulation curing process, enabling energy-saving and environmentally friendly production without high-temperature steam curing, meeting local environmental assessment requirements.

After adopting Hengde's developed automated high-precision block cutting machine, the cutting speed increased by 30% compared to the old production line equipment, cutting output increased by 50%, saving a large number of molds, raw materials, and labor costs.

1. Equipment order signing

2. Equipment delivery

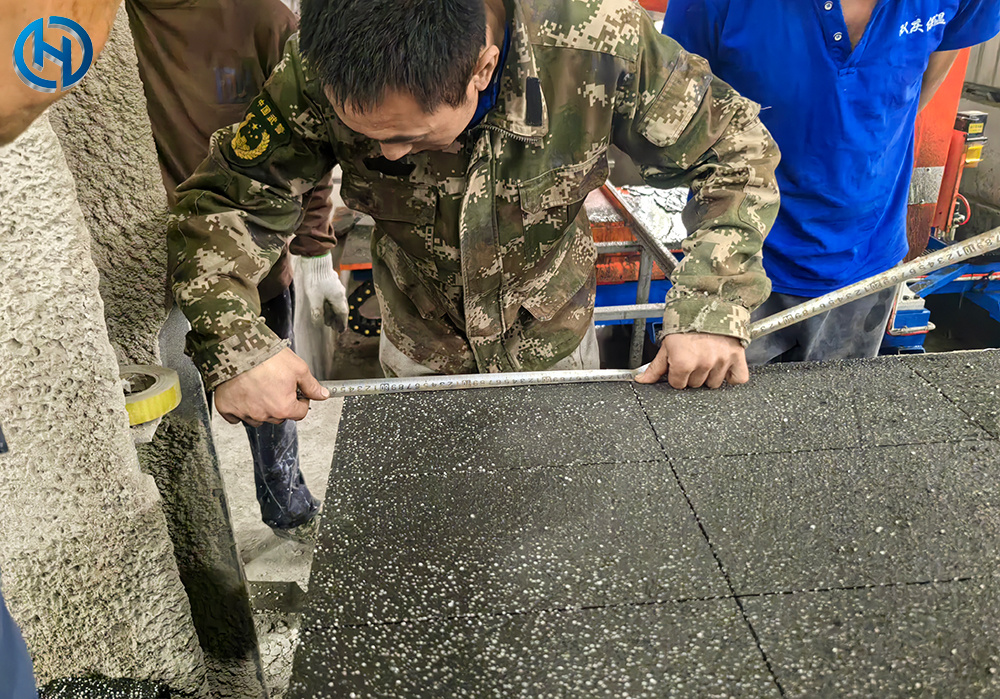

3. Equipment installation

4. Start production (product cutting)

5. Production and sales

Above: The customer's factory old equipment has stopped production and is far away

2026-01-21

No.25, Fulian Road, Fu'an Industrial Zone, Foshan City

No. 7, Jianyi Road, Xinjiang Wujiaqu Industrial Zone, Bingtuan New Building Materials Industrial Park

12 Potsdam Avenue, Berlin, Germany

WeChat Public Number

TikTok

Copyright©2014-2025 Guangzhou Hengde building materials Co. Ltd.