-

-

-

-

Technical Services

-

Video picture

05

2026

-

02

Africa South Africa Customer Self-Insulating Block Equipment Production Line Project (Commissioned)

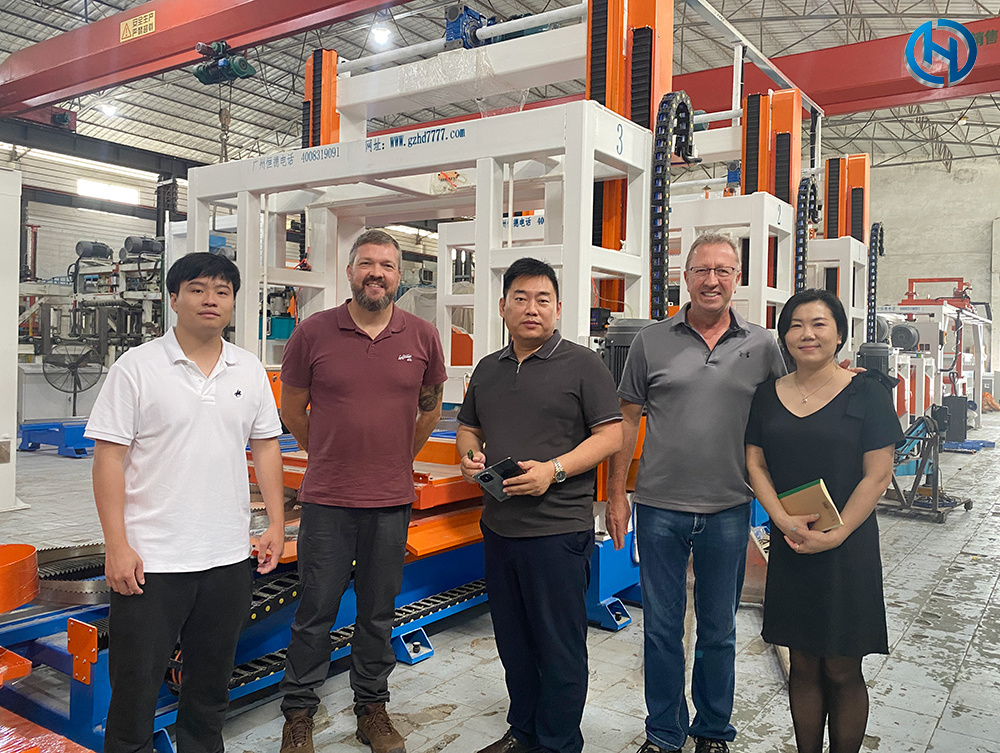

Recently, a South African customer signed a cooperation agreement with Guangzhou Hengde for a production line of self-insulating block equipment. This marks an important step for Guangzhou Hengde in deepening its presence in the South African and African markets.

During the factory tour, Hengde’s technical staff guided the customer through key production processes, including the mixing system, casting molds, and cutting equipment. On-site, the technicians demonstrated how to operate the mixer for blending raw materials and then poured the mixed material into standard molds to complete the initial casting process. Under the technicians’ guidance, the South African customer personally took charge of operating Hengde’s cutting equipment, experiencing its ease of use and intelligent features. The cutting dimensions were precise and accurate, with an error margin of less than 1 mm. The amount of cutting waste was minimal, and the finished products were aesthetically pleasing and free from damage.

During the inspection, both sides engaged in in-depth discussions centered on production requirements. The South African customer explicitly requested the production of bricks with dimensions of 600×250×100/140/200 mm, and stipulated that the dimensional tolerances for the mold blanks must be kept within 5 mm. In response to the customer’s needs, the company’s technical team provided the customer with a comprehensive plant construction investment plan.

After a period of careful consideration, the South African customer, after comparing equipment from several industry players, finally reached an agreement in principle to collaborate on a project with Guangzhou Hengde. The new high-speed cutting saw developed by Hengde addresses the shortcomings of traditional cutting processes, supports both long-mold and square-mold production, and has been recognized by the customer for its advantages: high mold turnover rate, stable daily output, and versatility—capable of handling multiple applications with a single machine.

I. Visit the factory

II. Online Signing

3. Equipment Shipment

IV. Equipment Installation

V. Put into Production

2026-01-21

No.25, Fulian Road, Fu'an Industrial Zone, Foshan City

No. 7, Jianyi Road, Xinjiang Wujiaqu Industrial Zone, Bingtuan New Building Materials Industrial Park

12 Potsdam Avenue, Berlin, Germany

WeChat Public Number

TikTok

Copyright©2014-2025 Guangzhou Hengde building materials Co. Ltd.