-

-

-

-

Technical Services

-

Video picture

08

2025

-

03

Southeast Asian Indonesian customer has put the block equipment into production.

Recently, a Southeast Asian customer from Indonesia conducted an in-depth inspection of the block equipment from Guangzhou Hengde Construction Technology Co., Ltd. and successfully signed a contract to purchase a set of equipment. The Indonesian customer chose us after visiting Hengde's production base on-site and comparing similar domestic equipment over a week. This cooperation not only reflects Guangzhou Hengde's leading position in the lightweight block equipment field but also further promotes infrastructure cooperation between China and India.

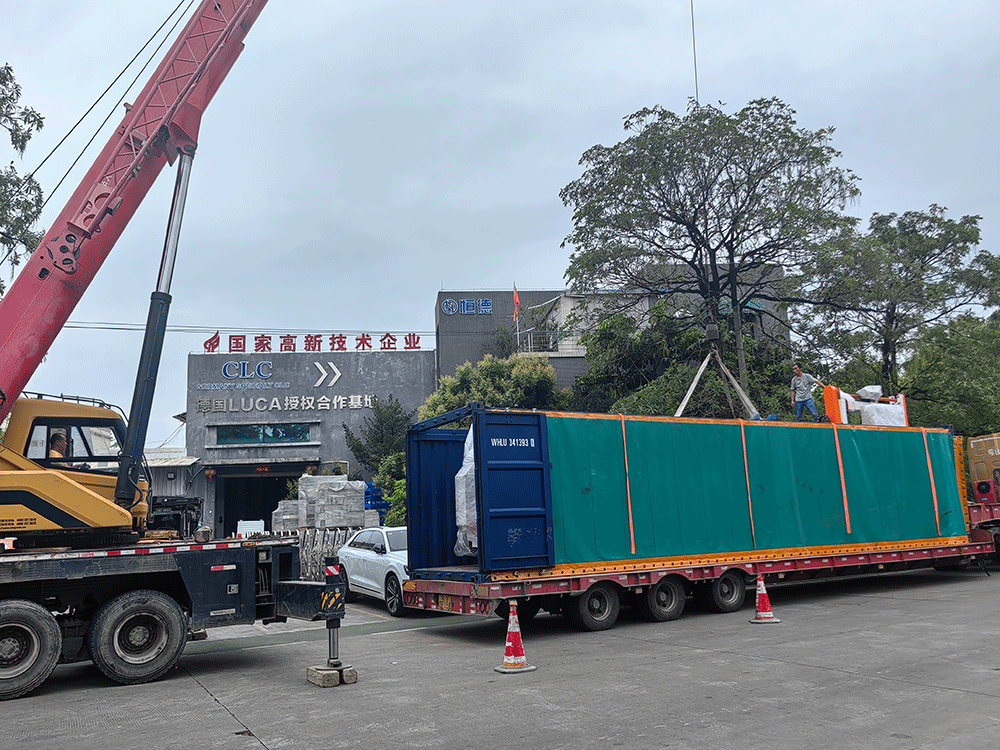

After a month of processing and production at Hengde's factory, the Indonesian customer's fully automatic lightweight block brick production line was delivered on time. It uses Hengde's newly developed dual-channel vertical cutting machine. This production line includes related supporting equipment such as mixing, demolding, peeling, cutting, and stacking. Hengde's factory completed the production tasks on time with guaranteed quality and quantity.

Hengde's independently developed dual-channel rotary vertical cutting saw uses online cutting technology to achieve high-precision processing through dual-channel cutting technology, improving cutting efficiency by more than 30% compared to traditional equipment. This technology has been successfully applied in Central Asia and Southeast Asian markets, with customer feedback indicating a cutting waste rate lower than the industry average. The production line supports the resource utilization of solid waste such as fly ash and construction waste, complying with Indonesia's environmental building material policy guidelines. Customer calculations show that raw material costs are reduced by 25% compared to traditional solutions, and the production process produces no wastewater discharge.

At the end of May, the equipment was shipped to the customer's factory, and the company's technical staff promptly followed up to guide the equipment installation and debugging work.

In early July, the equipment installation and debugging were completed, and the customer held an opening ceremony with local characteristics.

1. Inspection and Signing

2. Equipment Shipment

3. Equipment Installation

4. Factory Opening Ceremony

5. Production Commencement

No.25, Fulian Road, Fu'an Industrial Zone, Foshan City

No. 7, Jianyi Road, Xinjiang Wujiaqu Industrial Zone, Bingtuan New Building Materials Industrial Park

12 Potsdam Avenue, Berlin, Germany

WeChat Public Number

TikTok

Copyright©2014-2025 Guangzhou Hengde building materials Co. Ltd.