-

-

-

-

Technical Services

-

Video picture

11

2025

-

09

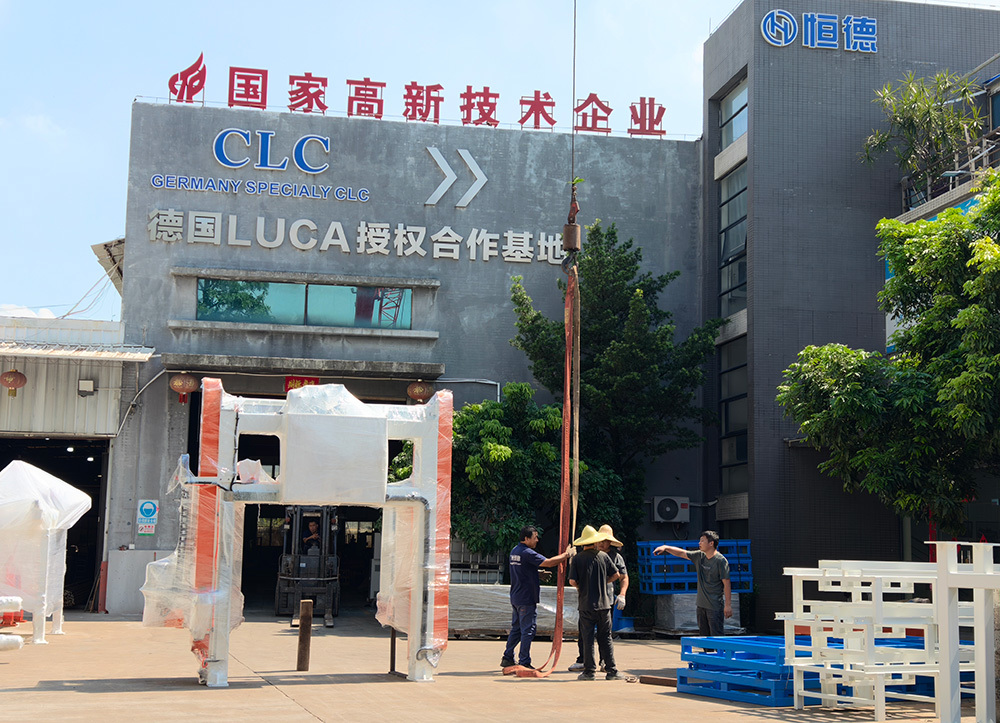

South African customer's lightweight block production line shipped

The South African customer’s lightweight brick equipment production line has been successfully shipped. The equipment includes a cutting machine, palletizer, shuttle car, clamp loader, mixer, and a range of other supporting devices. This production line will significantly enhance the customer’s manufacturing efficiency and product quality, providing strong support for their competitive edge in the market. We hope the equipment is installed and commissioned smoothly, helping the customer achieve early production!

In recent days, South African customers have received their lightweight brick equipment production lines in stages—seven truckloads in total, delivered over a span of four days. Guangzhou Hengde provided customized solutions tailored to the specific needs of the clients and the unique characteristics of local raw materials, ensuring the equipment perfectly matches South Africa’s market requirements for lightweight brick specifications. Previously, the customer’s existing old production line encountered various issues during daily operations, leading to low productivity and inconsistent product quality. To address these challenges, the customer decided to upgrade and overhaul their equipment. After extensive research and careful comparison among multiple suppliers, they ultimately chose Guangzhou Hengde’s lightweight wall material machinery.

This production line includes a series of core equipment such as cutting machines, palletizers, transfer vehicles, gripper machines, and mixers.

Cutting machine: Equipped with a single-head vertical cutting saw, it delivers fast cutting speeds and precise dimensions, making it ideal for slicing bricks into desired sizes.

Palletizer: Used for automating the stacking of bricks, enhancing production efficiency and operational safety.

Shuttle carts: Used for transporting bricks or other heavy materials, they typically provide efficient connections between different sections of the production line.

Clamp robot: A gripping and handling device commonly used to pick up and move bricks or other items during the production process.

Blender: Used to thoroughly mix various raw materials, ensuring the quality of the produced products remains stable and reliable.

These equipment combinations can effectively enhance the automation level of the production line and optimize manufacturing efficiency, especially in the production of lightweight bricks, where they help boost overall output while reducing labor costs.

Guangzhou Hengde, as a supplier of lightweight wall material equipment, has earned customer recognition for its advanced technology and reliable service, steadily expanding into the African market. This particular automated lightweight brick production line ordered by a South African client features stringent requirements for equipment quality and performance. Before delivery, every piece of machinery undergoes meticulous manufacturing and rigorous testing to ensure seamless operation.

South Africa,Lightweight brick equipment,Block Cutting Machine,Block Palletizer,Blender

No.25, Fulian Road, Fu'an Industrial Zone, Foshan City

No. 7, Jianyi Road, Xinjiang Wujiaqu Industrial Zone, Bingtuan New Building Materials Industrial Park

12 Potsdam Avenue, Berlin, Germany

WeChat Public Number

TikTok

Copyright©2014-2025 Guangzhou Hengde building materials Co. Ltd.