-

-

-

-

Technical Services

-

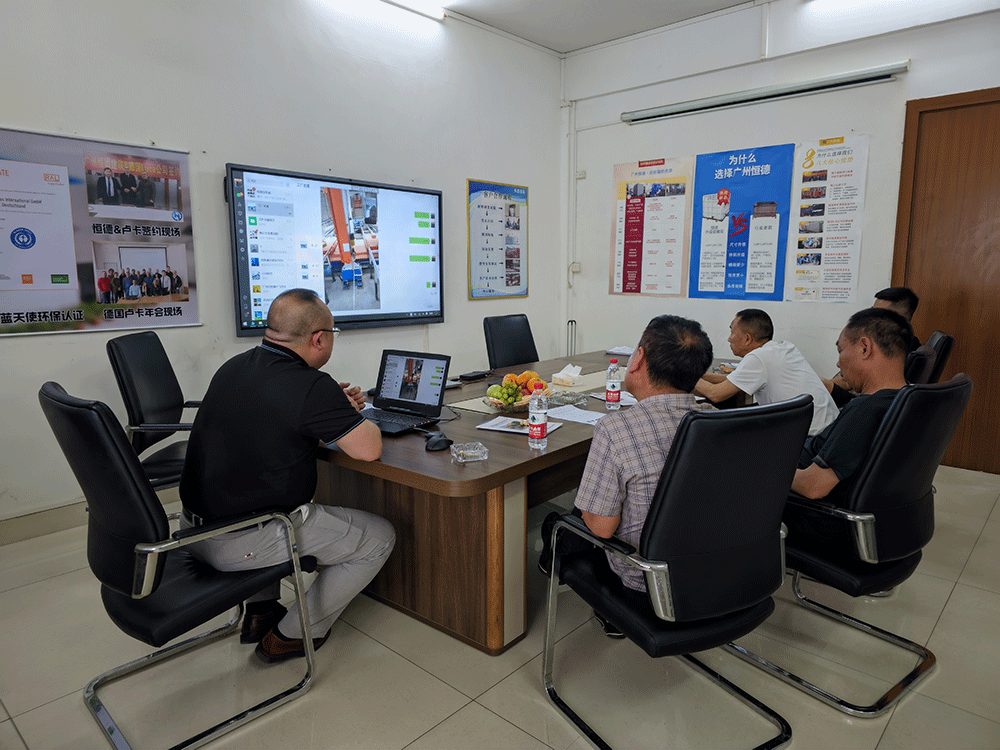

Video picture

27

2025

-

06

A customer from a sand and gravel plant in Enshi, Hubei visited Guangzhou Hengde to explore new opportunities for cooperation in the production of masonry units.

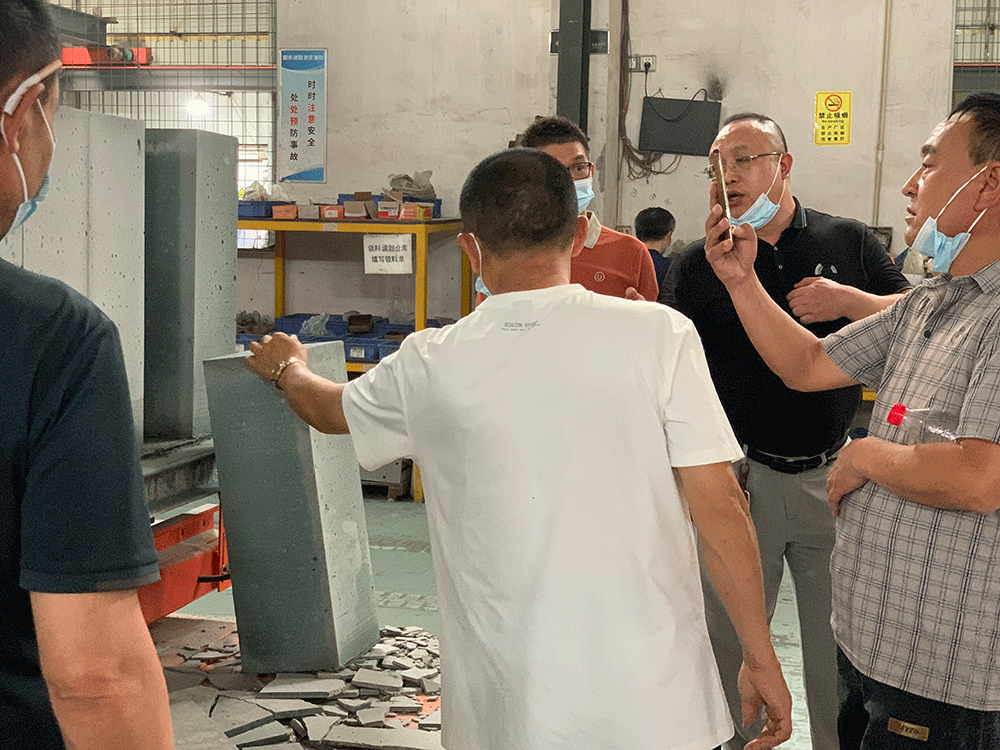

Recently, the person in charge of a certain sand and gravel plant in Enshi, Hubei Province, led a technical team to visit Guangzhou Hengde Construction Technology Co., Ltd. to conduct a field investigation on the resource utilization of sand and gravel waste and the construction of a masonry block production line. This investigation focused on "turning waste into treasure and green production." Both sides conducted in-depth exchanges on the characteristics of sand and gravel raw materials, equipment matching schemes, and capacity planning, laying a solid foundation for future cooperation.

Client visit

No.25, Fulian Road, Fu'an Industrial Zone, Foshan City

No. 7, Jianyi Road, Xinjiang Wujiaqu Industrial Zone, Bingtuan New Building Materials Industrial Park

12 Potsdam Avenue, Berlin, Germany

WeChat Public Number

TikTok

Copyright©2014-2025 Guangzhou Hengde building materials Co. Ltd.