-

-

-

-

Technical Services

-

Video picture

20

2025

-

06

Guangzhou Hengde signs contract with South African client for self-insulating masonry block production line, deepening market layout in Africa

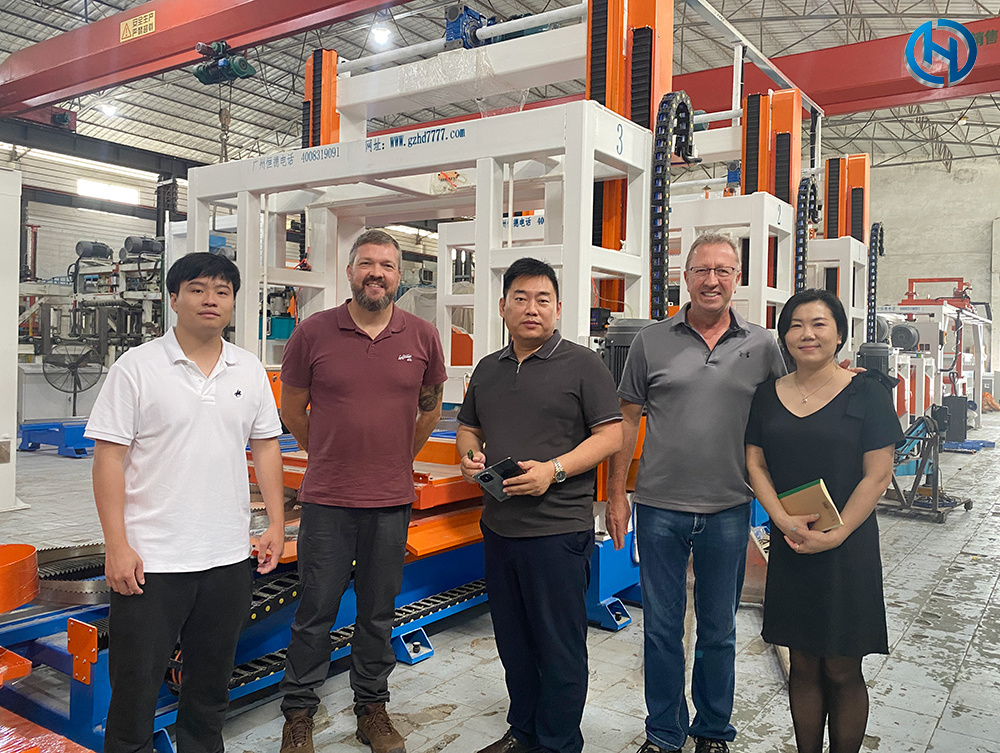

On June 13, Guangzhou Hengde Construction Technology Co., Ltd. and a South African client officially reached a procurement cooperation agreement for autoclaved aerated concrete (AAC) block equipment production lines through an online signing ceremony. After an on-site visit by the client on April 28-29, and a month of technical solution refinement, the online signing was completed without a second on-site meeting.

On June 13, Guangzhou Hengde Building Science and Technology Co., Ltd. and a South African client officially reached a procurement cooperation agreement for a self-insulating block equipment production line through online signing. After an on-site inspection from April 28 to 29, the client, after a month of technical solution refinement, completed the online signing without a second on-site meeting.

Early-stage investigation laid the foundation for trust

In late April, the South African client made a special trip to the Guangzhou Hengde production base for a two-day in-depth inspection. In the mixing process demonstration session, the client witnessed the precise measurement of raw materials such as cement and fly ash by the intelligent batching system, and the coordinated operation of the material storage tank and water metering device; in the cutting process, the client personally operated the self-insulating block production line for testing, and the cutting tolerance was stable at ±1mm. In response to the customer's demand for multi-specification production of 600×250×100/140/200mm, Hengde demonstrated the rapid mold switching technology on-site, completing the debugging of different specifications within 2 hours, fully demonstrating the flexible production capacity of the equipment.

Technical solution iteration: accurately responding to the needs of the African market

Cloud signing: digital cooperation opens a new paradigm

On June 13, both parties completed the signing through an online meeting. The self-insulating block production line procured this time includes a complete set of equipment such as an intelligent mixing system, multi-specification molds, and Hengde cutting equipment. The single-shift production capacity reaches 200 cubic meters, which can meet the needs of large-scale production for affordable housing projects in South Africa. The project has now entered the production scheduling stage, and it is expected to be completed within 60 working days. Hengde will adopt a "remote guidance + local training" model, dispatching technical experts to South Africa to assist with installation and providing 15 days of operation training for the customer team to ensure that the production line is put into operation quickly.

This cooperation is another breakthrough for Hengde in cultivating the African market. Its "on-site inspection + cloud iteration + digital delivery" full-process service model provides a replicable cooperation paradigm for Chinese lightweight building materials companies to go global.

Customer Case Studies,African market,Autoclaved aerated concrete (AAC) block production line

No.25, Fulian Road, Fu'an Industrial Zone, Foshan City

No. 7, Jianyi Road, Xinjiang Wujiaqu Industrial Zone, Bingtuan New Building Materials Industrial Park

12 Potsdam Avenue, Berlin, Germany

WeChat Public Number

TikTok

Copyright©2014-2025 Guangzhou Hengde building materials Co. Ltd.