16

2025

-

04

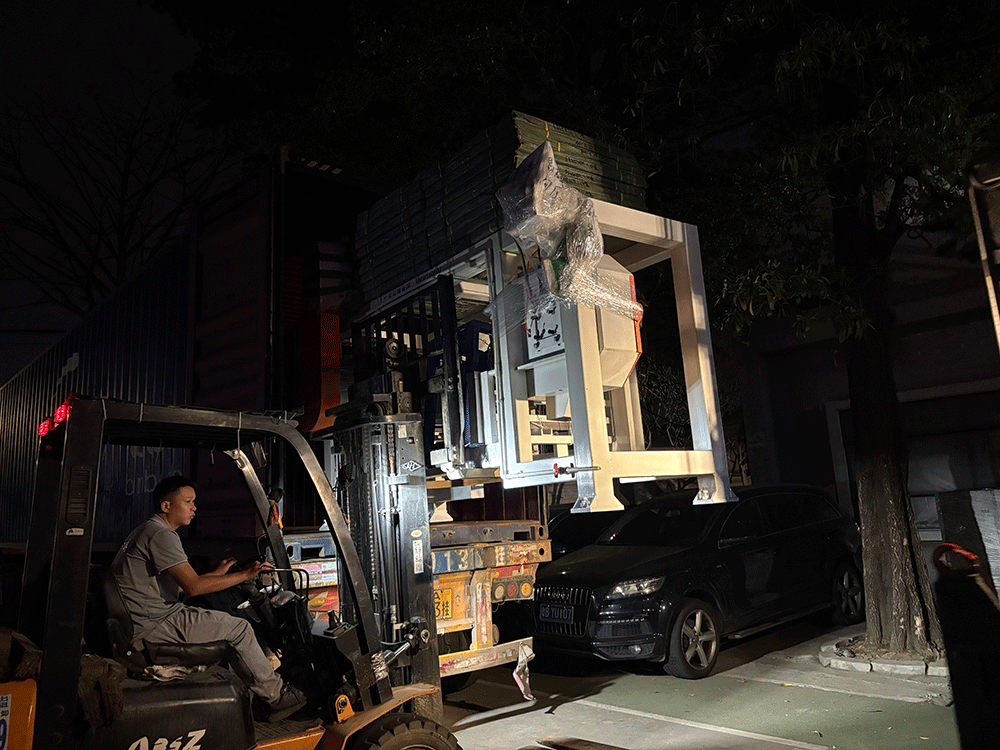

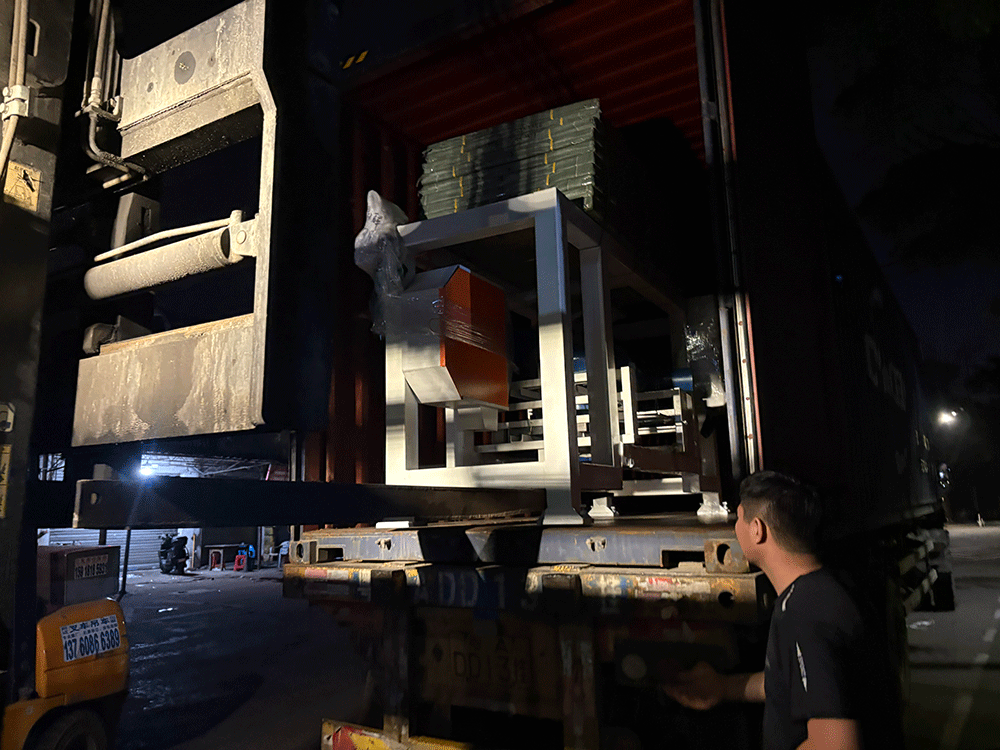

Urgent shipment of Indonesian customer's block production line at night to help customers seize the new building materials market

Recently, a complete automated lightweight block production line customized by Guangzhou Hengde for an Indonesian client was completed on schedule and shipped. After visiting several equipment manufacturers in China and inspecting Hengde's production base and core cutting technology, the client decided to sign a contract within a week and requested expedited production. From contract signing to equipment delivery, it only took 30 days. The urgent pace of night-time loading demonstrates the client's determination to seize the Southeast Asian market for new building materials.

Recently, a complete automated lightweight block production line customized by Guangzhou Hengde for an Indonesian client was completed on schedule and shipped. The client purchased a newly developed dual-lane vertical cutting machine from Hengde. The entire production line includes core equipment such as mixing, demolding, skin removal, cutting, and palletizing, and was urgently shipped from Guangzhou Hengde. After inspecting several equipment manufacturers in China and visiting Hengde's production base and core cutting technology, the client decided to sign a contract within a week and requested expedited production. From contract signing to equipment delivery, it only took 30 days. The urgent pace of nighttime loading demonstrates the client's determination to seize the Southeast Asian market for new building materials.

This Indonesian client has been deeply involved in the local catering and engineering fields for many years, accumulating rich industry experience and extensive customer resources. In the process of expanding its engineering business, the client keenly sensed new trends in the building materials market, and is particularly optimistic about the potential of environmentally friendly lightweight block bricks, a new type of building material. After comparing several equipment manufacturers, the client ultimately chose Guangzhou Hengde Architectural Technology Co., Ltd., mainly based on the following core advantages and technical characteristics.

I. Core Technological Advantages

Dual-lane Vertical Cutting Machine Innovative Technology

Hengde's self-developed dual-lane rotary vertical cutting saw uses online cutting technology. Through dual-lane cutting technology, high-precision processing is achieved, with a cutting tolerance of less than 1 mm, and cutting efficiency is increased by more than 30% compared to traditional equipment. This technology has been successfully applied in Southeast Asia, Russia, and Central Asia, and customer feedback indicates that the cutting waste rate is lower than the industry average.

Full-process Automated Integration

The production line covers mixing, demolding, skin removal, cutting, and palletizing. It is equipped with Hengde's patented square mold cutting system and supports a dual-mold production mode with a daily output of up to 150 cubic meters. The high degree of automation reduces manual intervention and ensures production stability.

II. Key Factors in Customer Decision-Making

On-site Inspection and Comparison Verification

The Indonesian client visited Hengde's production base, focusing on the lightweight block production line and cutting machine manufacturing workshop. After comparing with similar domestic equipment, the client recognized Hengde's outstanding performance in energy consumption control (comprehensive energy saving of 15%-20%) and product qualification rate (reaching 98.5%).

Raw Material Compatibility and Environmental Benefits

The production line supports the resource utilization of industrial solid waste such as fly ash and construction waste, in line with Indonesia's environmental building materials policy. Customer calculations show that raw material costs are reduced by 25% compared to traditional methods, and the production process has no wastewater discharge.

III. Project Delivery and Service Guarantee

Hengde has completed equipment production and delivered it on time. This cooperation marks the first entry of its lightweight block equipment into the Indonesian market. Previously, Hengde equipment has established successful cases in five Central Asian countries and Southeast Asian markets. Its technological iteration capabilities and after-sales service system are important considerations for long-term customer cooperation.

Lightweight blocks, as a new type of green building material, are favored in the global building market due to their outstanding advantages such as being lightweight, heat-insulating, soundproof, and fireproof. In recent years, infrastructure construction in Indonesia has continued to heat up, and the demand for high-quality building materials is growing. The client has seized this market opportunity and hopes to use Guangzhou Hengde's block production line to produce and promote environmentally friendly lightweight blocks locally, meeting the market's urgent need for new building materials and seizing market opportunities.

Client visit,Shipping from Indonesia,Foam concrete block equipment