OUR PRODUCTS

6 major product categories, more than 1000 products, quality international certification

PRODUCT ADVANTAGE

Eight product advantages

The introduction of a new generation of Lucca (LUCA)CLC blocks...

Introduction of German LUCA technology

Environmental protection process, energy saving and waste utilization

Technical reliability Industry standard setting

Independent technological innovation can not be copied

Introduction of German LUCA technology

Using German imported CLC foam concrete technology, Fully automatic intelligent equipment, non-autoclaved environmental protection process

Learn More

Environmental protection process, energy saving and waste utilization

Green environmental protection production mode, energy saving and low carbon, Waste water waste residue can be recycled in the production process

Learn More

Technical reliability Industry standard setting

Foam concrete self-insulation block, lightweight partition board for construction, recycled aggregate for construction waste, Drafting of industry standards such as "foam concrete block"

Learn More

Independent technological innovation can not be copied

Research and development of many technologies and equipment, such as "cement primary setting kiln", "multi-functional building materials all-in-one machine", "gantry numerical control flat cutting saw holding clip all-in-one machine", "high-precision gantry band saw cutting machine", "no pallet automatic packing line" and so on.

Learn More

Application research and development of new green wall materials

New high-precision blocks, waterproof blocks, high-precision waterproof wall panels, self-insulation wall panels and other production processes to meet assembly building applications and achieve different product functions.

Learn More

Multi-purpose gantry cutting saw

New research and development of high-speed high-precision cutting machine, suitable for all kinds of cement products cutting, cutting speed, high output, durable, less vulnerable

Learn More

Comprehensive utilization of solid waste tailings

Technical equipment and investment project plan for comprehensive development and utilization of bulk industrial solid waste, tailings slag, fly ash, stone waste mud and construction waste

Learn More

Production and installation training after-sales integration

Incoming material test, on-site production, planning workshop, technical training, after-sales improvement, provision of accessories, wearing parts replacement, technical upgrade

Learn More

Introduction of German LUCA technology

Environmental protection process, energy saving and waste utilization

Technical reliability Industry standard setting

Independent technological innovation can not be copied

Application research and development of new green wall materials

Multi-purpose gantry cutting saw

Comprehensive utilization of solid waste tailings

Production and installation training after-sales integration

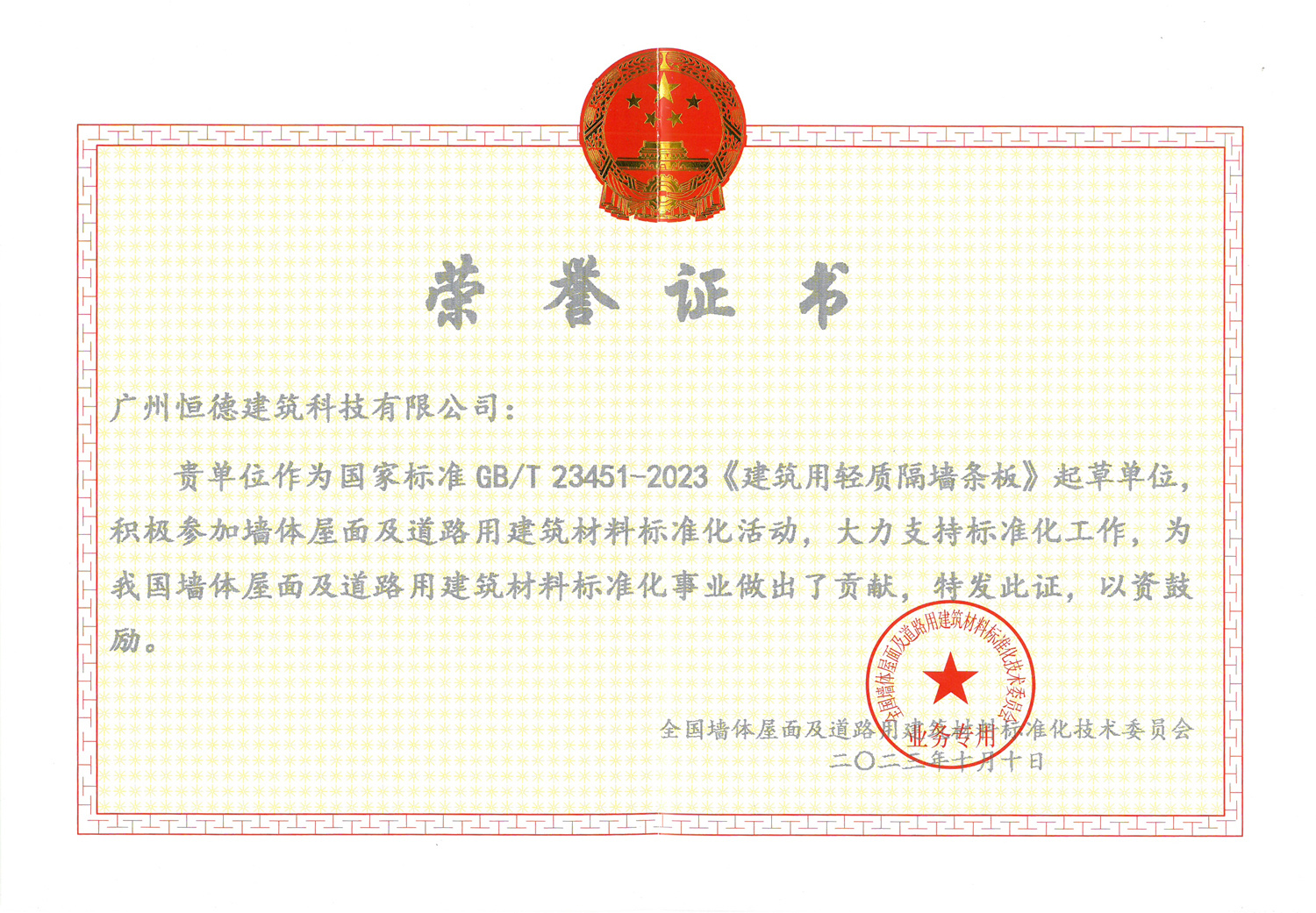

Five Reasons to Choose "Hengde"

Choose "Hengde" five reasons

Customer satisfaction is our eternal theme...

APPLICATION CASE

Industry Application Cases

EQUIPMENT TECHNOLOG

Guangzhou Hengde 12 core technology

Germany Lucca LUCA technology authorized enterprises

Core 1: Germany Lucca LUCA technology authorized enterprises

Foam concrete wall panel and roof panel

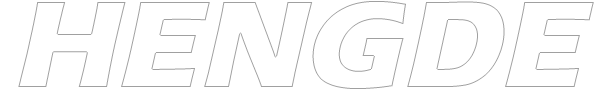

Core two: "foam concrete wall panels, roof panels" industry standard drafting unit

Recycled Aggregate for Construction Waste

Core three: "construction waste recycled aggregate" industry standard preparation unit

Foam concrete self-insulation block

Core four: "foam concrete self-insulation block" industry standard drafting unit

Light Partition Slats for Buildings

Core 5: National Standard Drafting Unit of "Light Partition Slab for Building"

Foam Concrete Block

Core six: "foam concrete block" industry standard drafting unit

Insulation slats for building partition walls

Core 7: National Standard Drafting Unit of "Insulation Slats for Building Partition Wall"

Building materials multi-function machine

Core eight: utility model patent: building materials all-in-one machine (patent number: ZL 201420061461.5)

foam concrete rotary cutting saw

Core 9: Utility Model Patent: Foam Concrete Rotary Cutting Saw Patent Number: ZL 201420061558.6)

Band saw cutting equipment adjustment mechanism

Core ten: technical invention patent: a cutting thickness adjustable multi band saw equipment (patent number: ZL 202110694572.4)

Automatic packing line without tray

Core 11: utility model patent: automatic packing line without tray (patent number: ZL 202222653646.2)

Special Initial Setting Kiln for Cement Foaming

Core 12: Curing Process: Special Initial Setting Kiln for Cement Foaming (Patent No.: ZL 201330371389.7)

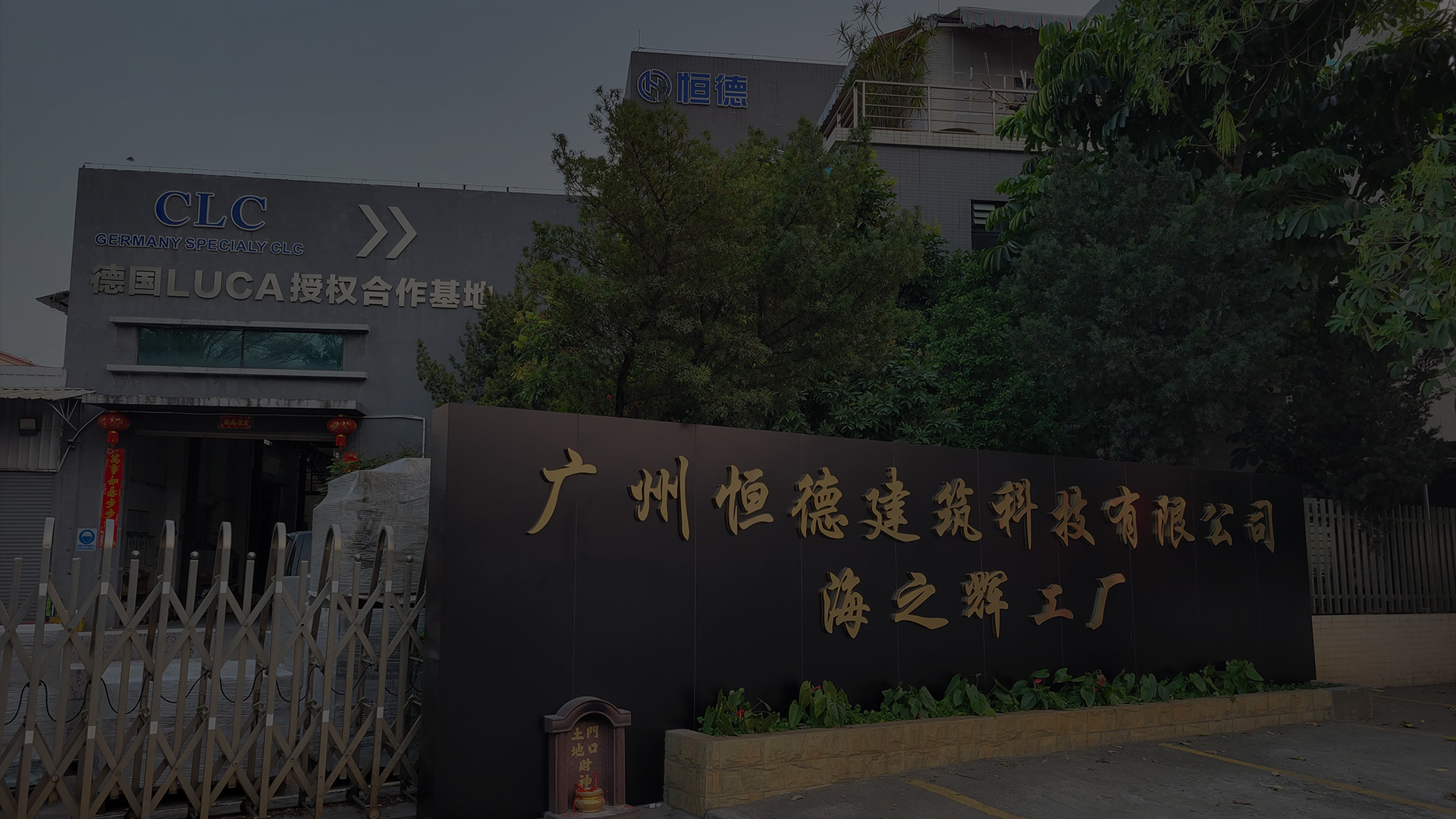

Entering Hange

Walk into Hengde

Service-based, quality-based survival, innovation and development

Founded in 2014

Guangzhou Hengde building materials Co. Ltd., referred to as Guangzhou Hengde, is located in the beautiful city of Guangzhou, China, specializing in the new import CLC wall material equipment, construction waste and industrial tailings comprehensive utilization of environmental protection building materials equipment manufacturing and new material technology research and development enterprises. In the past 20 years, Guangzhou Hengde has been rooted in Guangdong and facing the whole country. Now Guangzhou Hengde Construction Technology Co., Ltd. has set up subsidiaries in many places in Guangdong, including Shenzhen Hengde, Dongguan Hengde, Guangdong Luca Intelligent (Localized Equipment), Foshan Luca, Xinjiang Luca, Foshan Haizhihui Company, etc.

development process

Patent Certificate

Marketing Network

Production Environment

Company Culture

Network of service centers covering 6 cities across the country

Network of service centers covering 6 cities across the country

Guangzhou Hengde provides multi-faceted support from equipment design, research and development, component factory, after-sales service and technical patents, and can provide perfect project solutions according to the different needs of customers.

Design

Custom

R & D

Aftermarket

Information Hotline

NEWS

Learn more about Hengde Dynamics

Customer satisfaction is our eternal theme...

2025-10-23

2025-10-15

2025-10-11