Polystyrene particle self-insulation block equipment

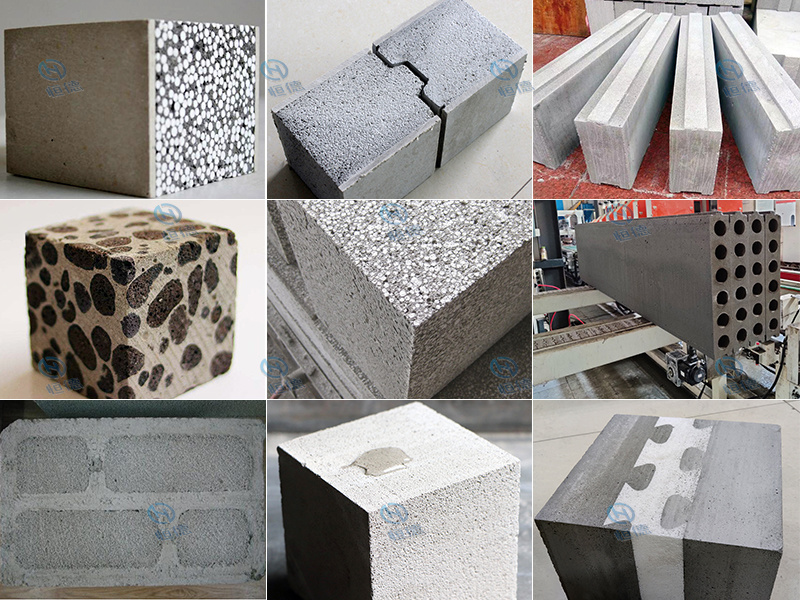

The polystyrene particle self-insulation block equipment adopts CLC technology imported from Germany, which can produce polystyrene particle block, polystyrene block, EPS block, eps composite self-insulation block, polystyrene particle lightweight aggregate concrete block and other products.

Product accessories:

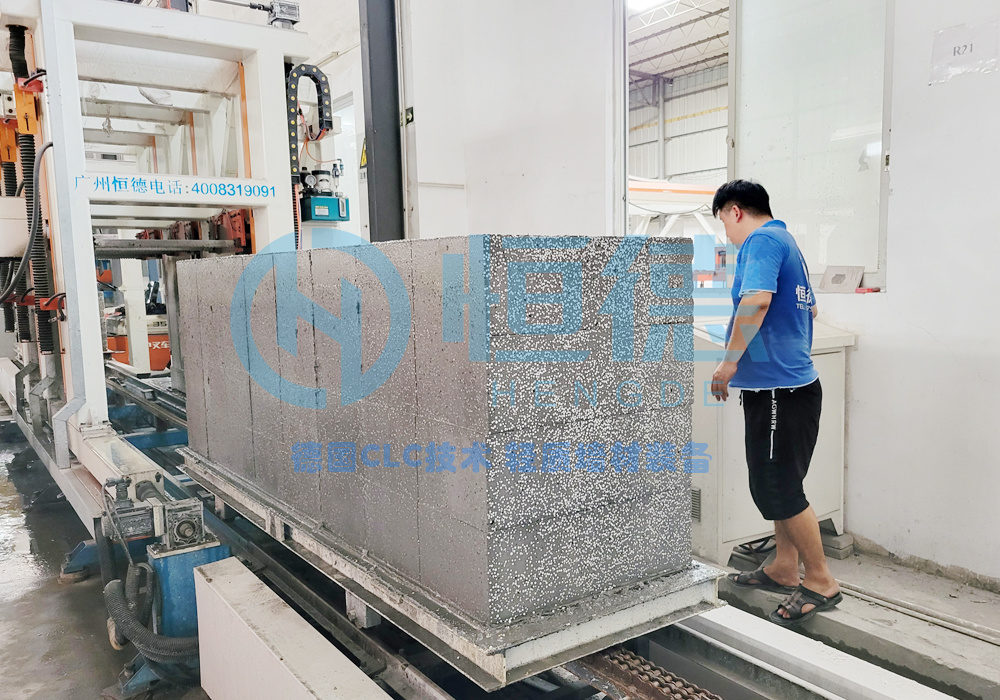

Self-insulation block equipment

keyword: Polystyrene particle self-insulation block equipment

- Product Description

-

Polystyrene particle self-insulation block is a building energy-saving and structural integration technology, which integrates building insulation function and wall enclosure function. The wall does not need to take additional insulation measures to meet the requirements of the current building energy-saving standards, and realizes a new type of insulation system with the same service life as the wall. The promotion and application of integrated technology is a major reform of traditional architectural design and construction, and is one of the effective ways to fundamentally solve the quality safety and fire prevention problems of thermal insulation engineering.

Performance and advantages of polystyrene particle self-insulation block equipment

1. Full-automatic production line: full-automatic production line, numerical control operation, saving labor and time; Automatic metering, feeding, pouring and stirring; Low labor intensity, female workers can operate.

2. Waterproof block brick technology: using German imported formula and production technology, block brick has good waterproof performance, which can effectively solve the problems of empty drum, peeling and water seepage of autoclaved aerated block.

3. High-precision and high-speed cutting system: newly developed high-precision block and wallboard slotting machine with standard size, no damage and no batch ash. Suitable for long mold boxes and square mold boxes, can cut various sizes and specifications, with small waste and low cost. The newly developed high-speed cutting saw has high cutting speed, higher stability, strong durability and more convenient maintenance. (There are many models of this cutting saw, for customers to choose according to their needs)

4. Self-heating cycle curing process: it adopts unique self-heating cycle curing system (can be equipped with new air energy curing), non-autoclaved production mode, no need for high temperature autoclaving, low energy consumption, environmental protection and energy saving, and good environmental impact assessment.

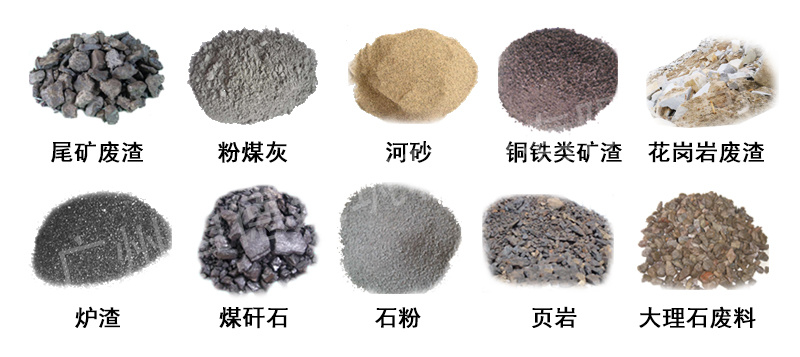

5. Selection of raw materials for production: there are many choices of raw materials, which can be obtained locally, such as sand, fly ash, slag, stone powder, phosphogypsum, slag, industrial tailings, construction waste, etc., with low production cost.

6. Provide a complete set of project solutions: (one machine with multiple functions) The company will help you analyze production costs, product profits, market prospects and investment plans for plant construction according to your local raw material prices and market conditions. polystyrene particles from insulation block equipment quotation provided free of charge, project reports, photo information etc. From the initial stage of the project to the commissioning of the plant, the company will develop a comprehensive project investment plan.

The investment requirements for the project to build a factory For the cooperative customers, the company will provide the customers with the planning and design of the factory free of charge. You are welcome to bring your factory drawings when you come to the factory for inspection.

Powerhouse and water and electricity requirements

Production plant area: 20-60 meters wide, 80-200 meters long and 6 meters high. Product maintenance area: 2000-8000 square meters (the above can be flexibly adjusted according to the output of the equipment)

Water: 80-500 tons/day;

Electricity consumption: 200-800 kW (total power)

Total factory area: 8-30 mu of land (flexibly adjusted according to sales volume)

Production raw materials: 1. Cement: 425R Portland cement (required);2.EPS polystyrene particles (required);3. Fly ash (optional);4. Stone powder fine powder (optional);5. Sand (silt content ≤ 2% (optional);6. Slag powder and fine powder (optional);7. Additives (provided by the company)

Hengde polystyrene particle self-insulation block product features:

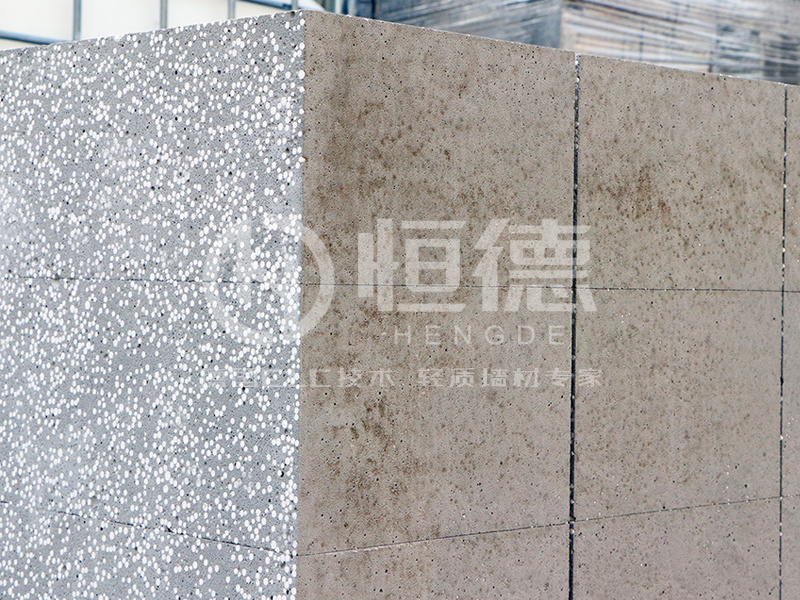

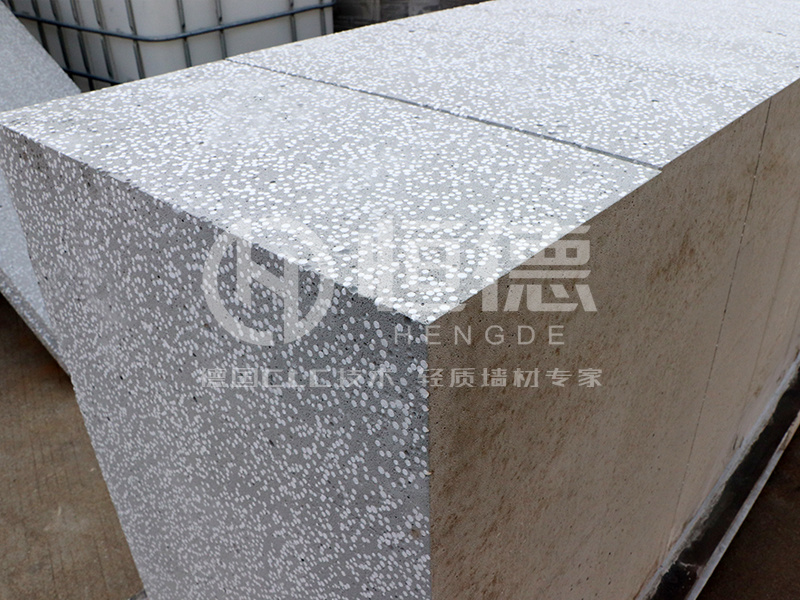

1. Lightweight. Polystyrene particle block with polystyrene foam particles, foam concrete as raw materials, volume density of 500-800kg/m3, can reduce the main load and investment costs.

2, the effect advantage. Polystyrene particle block water absorption is small, can reduce the internal and external wall surface hollowing, cracking and other series of ills, at the same time, the product can improve the strength level (A2.5-A3.5) according to the design requirements.

3, low cost. Polystyrene particle block, due to its own heat transfer coefficient and thermal inertia index has reached the energy-saving requirements (energy saving of more than 60%), the wall does not need to do external insulation treatment, thus reducing the construction cost.

4. Heat preservation and energy saving. Polystyrene particle block contains the characteristics of polystyrene foam particles and foam concrete. Its thermal insulation and wall are "two in one" without additional external thermal insulation, which can avoid the common problems of falling off and cracking of the outer protective layer of the outer wall.

5. Construction efficiency. Polystyrene particle block in accordance with the specifications for convenient construction, is a product that everyone understands, simple and fast construction.

Related Products

online message

We will contact you as soon as possible