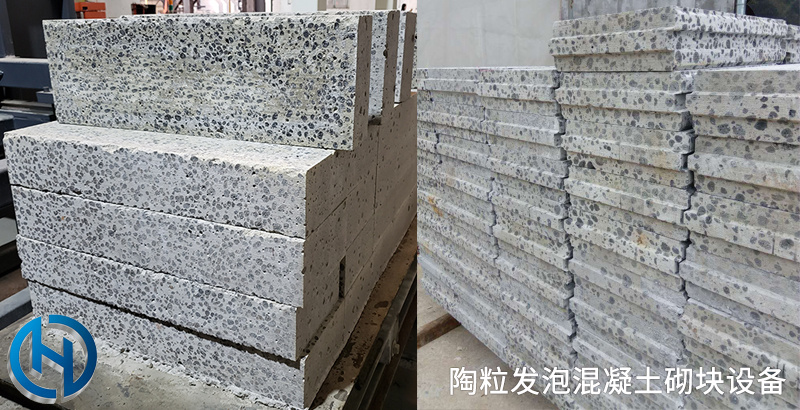

Ceramsite block equipment

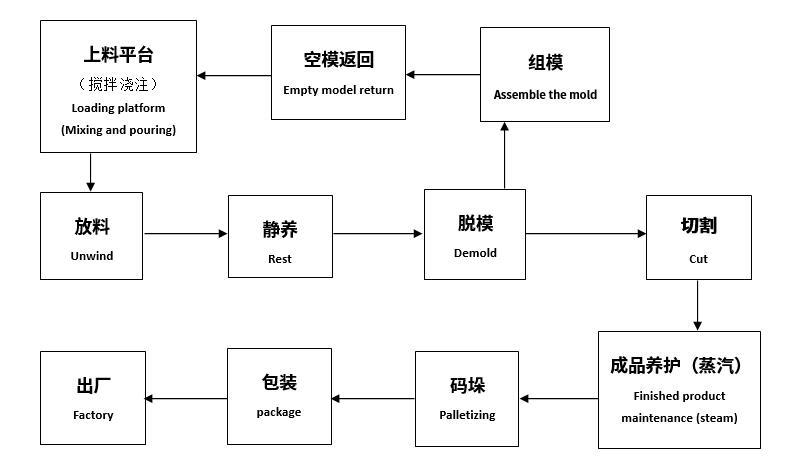

Guangzhou Hengde's new generation of ceramsite block equipment introduces German CLC block production technology and equipment. After mixing-foaming-injection molding-curing-demolding-cutting-palletizing-finished products and other technological processes, it is fully automatic, simple and convenient to operate, with large output and high return on investment.

Product accessories:

keyword: Ceramsite block equipment

- Product Description

-

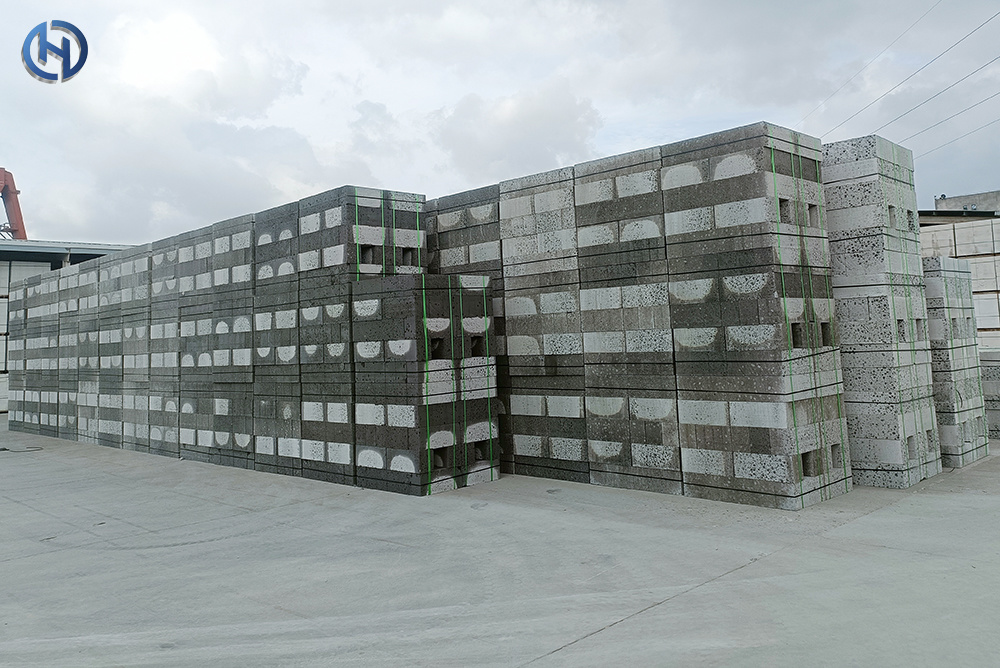

ceramsite block It is a new type of thermal insulation and energy-saving wall material, also known as ceramsite foamed concrete block, which is widely used. They are cement, fly ash, ceramsite as the main raw material, mixed with the right amount of industrial waste, by mechanical mixing, vibration molding, demoulding and maintenance of new wall materials. This new wall material product conforms to the national land saving, energy saving and environmental protection policies, and has good social and economic benefits.Ceramsite block equipment Using German imported CLC block production technology and equipment, after mixing-foaming-injection molding-maintenance-demoulding-cutting-palletizing-finished products and other technological processes, fully automatic operation, the whole process is simple and convenient to operate, convenient maintenance, saving labor, large output, high return on investment, is a new type of environmental protection wall material production equipment.

1. Germany imported CLC technology and inorganic nano-concrete technologyThe Company Ceramsite foam concrete block equipment Using the German Luca authorized CLC foam concrete technology and the Massachusetts Institute of Technology Professor Zeng Tingying inorganic nano concrete technology. Greatly improve the strength of lightweight concrete products, waterproof, insulation and production of environmental protection. It is more environmentally friendly and energy-saving than the traditional autoclaved aerated block production process, and the product quality is better.

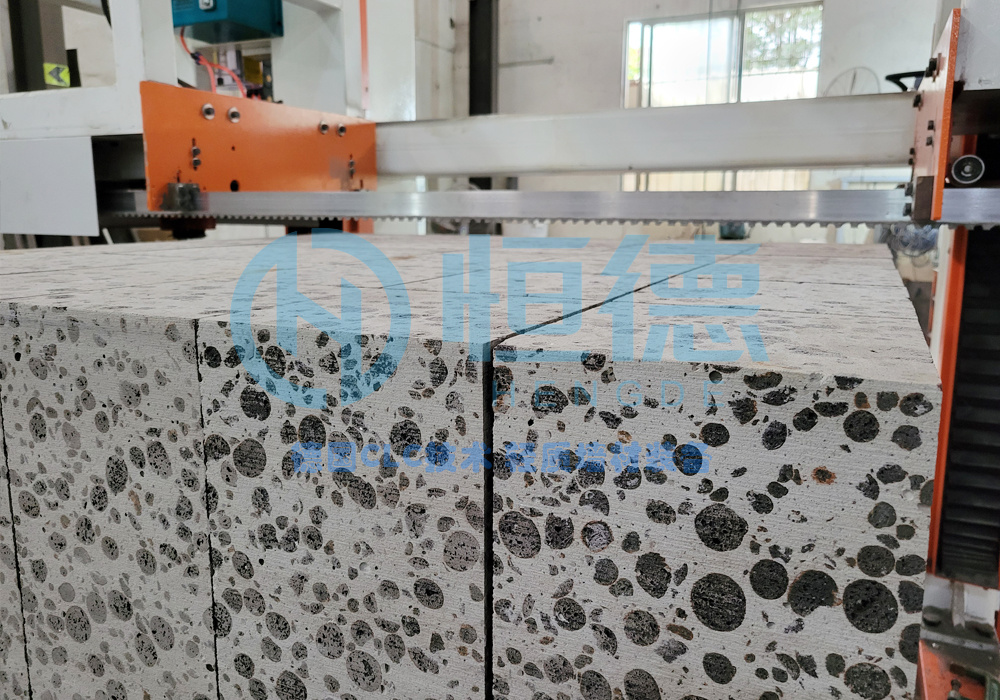

1. Germany imported CLC technology and inorganic nano-concrete technologyThe Company Ceramsite foam concrete block equipment Using the German Luca authorized CLC foam concrete technology and the Massachusetts Institute of Technology Professor Zeng Tingying inorganic nano concrete technology. Greatly improve the strength of lightweight concrete products, waterproof, insulation and production of environmental protection. It is more environmentally friendly and energy-saving than the traditional autoclaved aerated block production process, and the product quality is better. 2. compared to other manufacturers, hengde ceramsite self insulation block equipment what are the advantages?Ceramsite self-insulation block equipment production line Using German imported technology and formula, a new generation of non-autoclaved environmental protection technology, mature and reliable technology, not domestic manufacturers can compare.1. Fully automatic production line:Fully automatic production line, numerical control operation, saving labor and time; Automatic metering of feeding, pouring and mixing; Low labor intensity, female workers can operate.2. High-precision high-speed cutting system:New research and development of high-precision block, wallboard slotting machine, size standard, no damage, no batch of ash. Suitable for long mold boxes and square mold boxes, can cut various sizes and specifications, with small waste and low cost.The newly developed high-speed cutting saw has high cutting speed, higher stability, strong durability and more convenient maintenance.(This cutting saw has a variety of models, according to demand for customers to choose)

2. compared to other manufacturers, hengde ceramsite self insulation block equipment what are the advantages?Ceramsite self-insulation block equipment production line Using German imported technology and formula, a new generation of non-autoclaved environmental protection technology, mature and reliable technology, not domestic manufacturers can compare.1. Fully automatic production line:Fully automatic production line, numerical control operation, saving labor and time; Automatic metering of feeding, pouring and mixing; Low labor intensity, female workers can operate.2. High-precision high-speed cutting system:New research and development of high-precision block, wallboard slotting machine, size standard, no damage, no batch of ash. Suitable for long mold boxes and square mold boxes, can cut various sizes and specifications, with small waste and low cost.The newly developed high-speed cutting saw has high cutting speed, higher stability, strong durability and more convenient maintenance.(This cutting saw has a variety of models, according to demand for customers to choose)

3. New design palletizing packaging line

Fully automatic pallet-free packaging line, save a lot of mold bottom, reduce costs, equipment operation stability and high efficiency, to solve the problem of product adhesion.

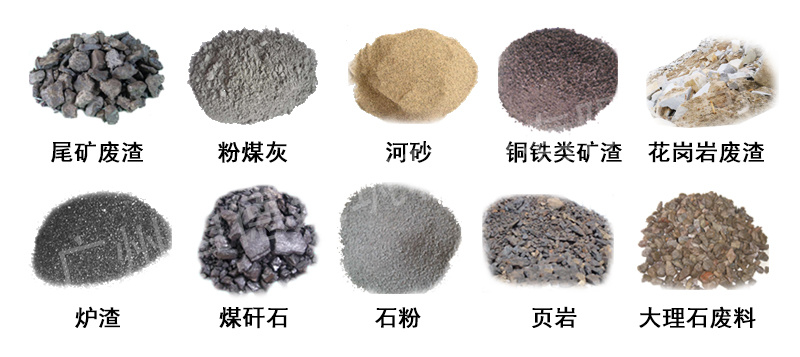

4. Self-heating cycle curing process:The use of unique self-thermal cycle maintenance system (can be equipped with new Air energy conservation), non-autoclaved production method, no need for high temperature autoclaving, low energy consumption, environmental protection and energy saving, and good environmental assessment.5. Selection of raw materials for production:There are many choices of raw materials, which can be used locally, such as sand, fly ash, slag, stone powder, phosphogypsum, slag, industrial tailings, construction waste, etc., and the production cost is low.

4. Self-heating cycle curing process:The use of unique self-thermal cycle maintenance system (can be equipped with new Air energy conservation), non-autoclaved production method, no need for high temperature autoclaving, low energy consumption, environmental protection and energy saving, and good environmental assessment.5. Selection of raw materials for production:There are many choices of raw materials, which can be used locally, such as sand, fly ash, slag, stone powder, phosphogypsum, slag, industrial tailings, construction waste, etc., and the production cost is low. The company undertakes the development of new environmental protection wall materials such as various industrial tailings, waste residue and construction waste.6. Provide a complete set of project solutions: (one machine with multiple functions)The company will help you analyze the production cost, product profit, market prospect and plant investment plan according to your local raw material price and market situation. ceramsite foam block equipment quotation provided free of charge, project reports, photo information etc. From the initial stage of the project to the commissioning of the plant, the company will develop a comprehensive project investment plan.

The company undertakes the development of new environmental protection wall materials such as various industrial tailings, waste residue and construction waste.6. Provide a complete set of project solutions: (one machine with multiple functions)The company will help you analyze the production cost, product profit, market prospect and plant investment plan according to your local raw material price and market situation. ceramsite foam block equipment quotation provided free of charge, project reports, photo information etc. From the initial stage of the project to the commissioning of the plant, the company will develop a comprehensive project investment plan. 3. enterprise strength witness

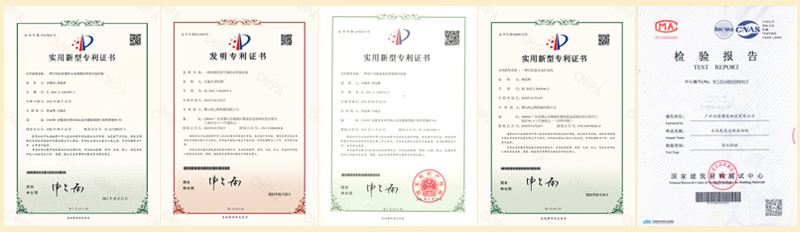

3. enterprise strength witness

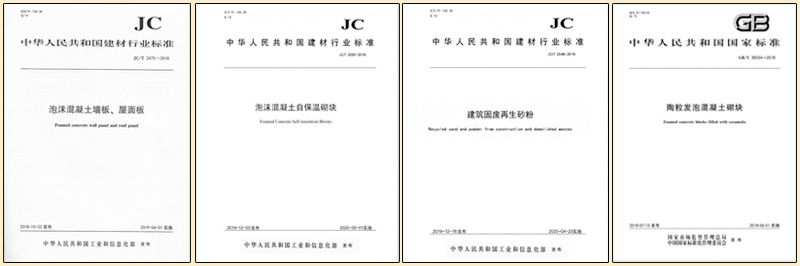

A number of industry standards, building energy-saving product certification4. project construction investment requirementsFor cooperative customers, the company will provide customers with factory planning and design free of charge. You are welcome to bring your factory drawings when you visit the factory.(I) powerhouse and water and electricity requirementsProduction plant area: 20-60 meters wide, 80-200 meters long, 6 meters highProduct maintenance area: about 2000-8000 square meters (the above can be flexibly adjusted according to the output of the equipment)Water consumption: 80-500 tons/day; Electricity consumption: 200-800 kW (total power)Total factory area: 8-30 mu of land (flexibly adjusted according to sales volume)Raw material requirements for (II) production1. Cement: 425R Portland cement (required);2. Selected ceramsite; 3. Fly ash and stone powder fine powder (optional);4. Sand (silt content ≤ 2% (optional);5. Slag powder fine powder (optional);6. Additives (provided by the company)

A number of industry standards, building energy-saving product certification4. project construction investment requirementsFor cooperative customers, the company will provide customers with factory planning and design free of charge. You are welcome to bring your factory drawings when you visit the factory.(I) powerhouse and water and electricity requirementsProduction plant area: 20-60 meters wide, 80-200 meters long, 6 meters highProduct maintenance area: about 2000-8000 square meters (the above can be flexibly adjusted according to the output of the equipment)Water consumption: 80-500 tons/day; Electricity consumption: 200-800 kW (total power)Total factory area: 8-30 mu of land (flexibly adjusted according to sales volume)Raw material requirements for (II) production1. Cement: 425R Portland cement (required);2. Selected ceramsite; 3. Fly ash and stone powder fine powder (optional);4. Sand (silt content ≤ 2% (optional);5. Slag powder fine powder (optional);6. Additives (provided by the company)

5. factory equipment delivery

5. factory equipment delivery 6. Customer Success Stories

6. Customer Success Stories

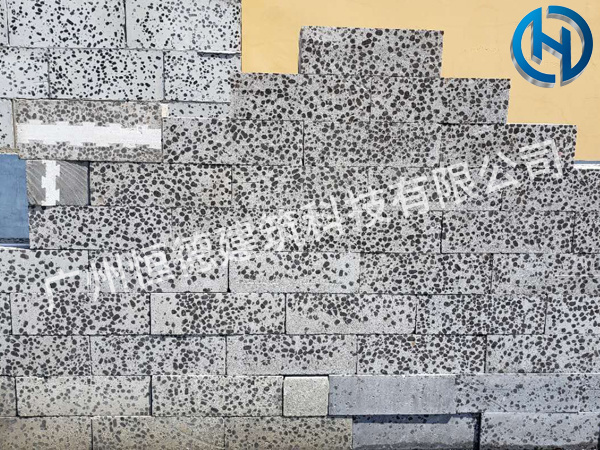

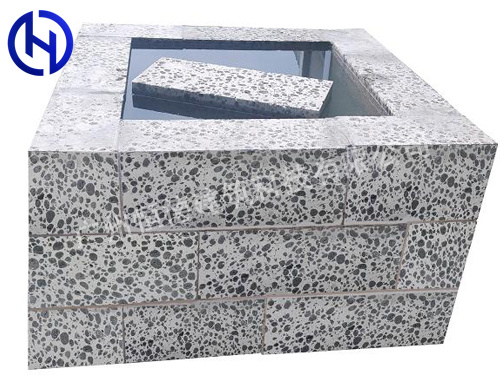

7. ceramsite self-insulation block product application case

7. ceramsite self-insulation block product application case 8. ceramsite self insulation block product advantages:Ceramsite self-insulation block alone can meet the current building energy-saving design requirements, no need to do other insulation treatment, can achieve the same life of building insulation and structure, compared with the external wall insulation, can effectively reduce the overall cost of construction and the total economic cost of the construction operation cycle, the economic benefits are huge. The product shall meet the requirements of national standard GB/T36534-2018 Ceramic Foamed Concrete Block.

8. ceramsite self insulation block product advantages:Ceramsite self-insulation block alone can meet the current building energy-saving design requirements, no need to do other insulation treatment, can achieve the same life of building insulation and structure, compared with the external wall insulation, can effectively reduce the overall cost of construction and the total economic cost of the construction operation cycle, the economic benefits are huge. The product shall meet the requirements of national standard GB/T36534-2018 Ceramic Foamed Concrete Block. 1. Convenient construction. As a wall material, ceramsite block can reduce the labor intensity of workers, save labor and materials, and paint is not hollowing and not prone to gaps.2. Good sound insulation performance. Ceramsite block because it is the main component of the ceramsite, ceramsite itself of the internal structure of the fine honeycomb microporous, plus for the external wall of the ceramsite block has a hollow design. These characteristics determine the excellent sound insulation performance of ceramsite blocks.3. Good insulation performance. The ceramsite self-insulation block can fully meet the building energy-saving requirements of different regions (increase the thickness in cold areas), and there is no need to make internal and external insulation layers. The raw materials of the product are inorganic non-combustible, which eliminates the fire hazard caused by the external thermal insulation composite material of the wall.4. Small water absorption and strong impermeability. Because the special ceramsite used in the ceramsite block is hydrophobic, combined with the high-efficiency composite closed-cell foaming technology, the water absorption rate of the ceramsite block is greatly reduced, which is the 1/4 water absorption rate of the autoclaved aerated block.5, light weight, reduce the overall load of the building. The dry density of self-insulating ceramsite block is 400-800kg/m3, which is 1/4 of concrete and 1/3 of clay brick, which can reduce the wall load by 50-60%, reduce the building weight by 20-30%, and the construction speed is fast, greatly reducing the labor intensity and construction cost of workers.

1. Convenient construction. As a wall material, ceramsite block can reduce the labor intensity of workers, save labor and materials, and paint is not hollowing and not prone to gaps.2. Good sound insulation performance. Ceramsite block because it is the main component of the ceramsite, ceramsite itself of the internal structure of the fine honeycomb microporous, plus for the external wall of the ceramsite block has a hollow design. These characteristics determine the excellent sound insulation performance of ceramsite blocks.3. Good insulation performance. The ceramsite self-insulation block can fully meet the building energy-saving requirements of different regions (increase the thickness in cold areas), and there is no need to make internal and external insulation layers. The raw materials of the product are inorganic non-combustible, which eliminates the fire hazard caused by the external thermal insulation composite material of the wall.4. Small water absorption and strong impermeability. Because the special ceramsite used in the ceramsite block is hydrophobic, combined with the high-efficiency composite closed-cell foaming technology, the water absorption rate of the ceramsite block is greatly reduced, which is the 1/4 water absorption rate of the autoclaved aerated block.5, light weight, reduce the overall load of the building. The dry density of self-insulating ceramsite block is 400-800kg/m3, which is 1/4 of concrete and 1/3 of clay brick, which can reduce the wall load by 50-60%, reduce the building weight by 20-30%, and the construction speed is fast, greatly reducing the labor intensity and construction cost of workers. Production process flow chartAbout equipment price:Due to different output, different configuration,Ceramsite self-insulation block equipmentPrices vary. Guangzhou Hengde green wall material equipment can be used in one machine. Replacement of auxiliary equipment and formula can produce a variety of products. We will make configuration adjustments according to customer needs, and the company project manager will provide youCeramsite self-insulation block equipmentQuotation, project report, picture data, etc.Welcome to make an appointment in advance (hotline: 400-831-9091) to visit our Foshan factory to see the equipment and production process. We are not afraid to compare with other manufacturers.

Production process flow chartAbout equipment price:Due to different output, different configuration,Ceramsite self-insulation block equipmentPrices vary. Guangzhou Hengde green wall material equipment can be used in one machine. Replacement of auxiliary equipment and formula can produce a variety of products. We will make configuration adjustments according to customer needs, and the company project manager will provide youCeramsite self-insulation block equipmentQuotation, project report, picture data, etc.Welcome to make an appointment in advance (hotline: 400-831-9091) to visit our Foshan factory to see the equipment and production process. We are not afraid to compare with other manufacturers.

Pre: Ceramsite block cutting machine

Next: None

Related Products

online message

We will contact you as soon as possible