EPS polystyrene particle partition board equipment

Guangzhou Hengde EPS polystyrene particle partition board equipment process is stable and the technology is easy to master. Products are widely used in interior walls, exterior walls, roof walls, fences, etc.

Product accessories:

Light partition board equipment

keyword: EPS polystyrene particle partition board equipment

- Product Description

-

EPS polystyrene particle partition board As a new wall material, it is widely used in interior walls, exterior walls, roof walls, fences, etc., which can speed up the construction speed, reduce labor intensity, shorten the construction period, reduce the project cost, and effectively improve the use area of buildings. It is the direction of wall reform.

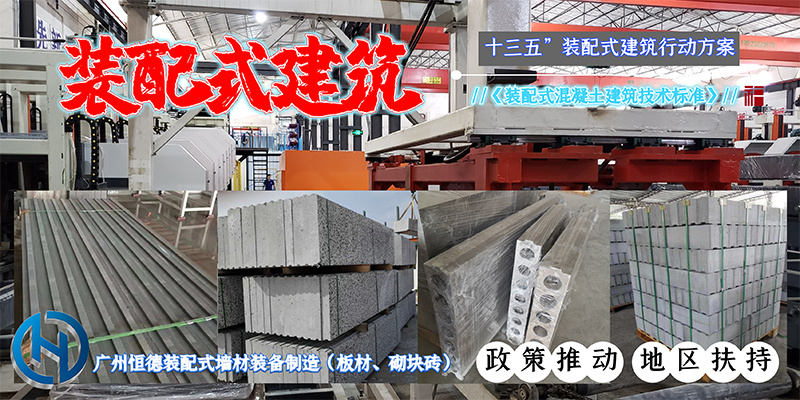

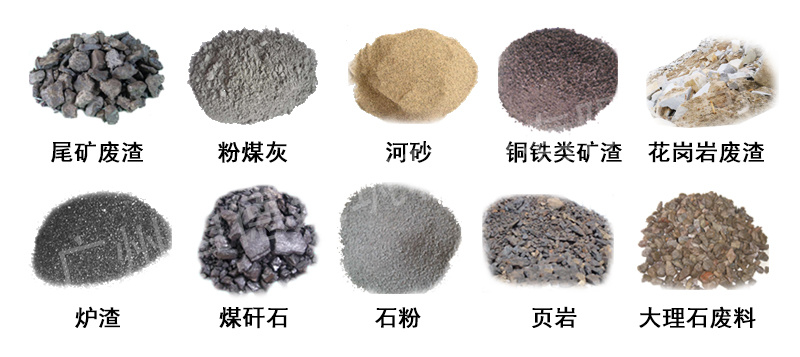

1. new EPS polystyrene particle wall board project advantages:1. The low-carbon, environmental protection, energy-saving, and waste-friendly projects supported by the government are in line with national industrial policies and enjoy multiple policy support such as tax exemption, subsidies for waste-friendly projects, and high-tech research and development funding.2. Industrial and agricultural solid waste (such as fly ash, coal gangue, quartz sand, tailings sand, rice bran, wheat straw, cotton stalk, sawdust, etc.) as raw materials, easy to buy, cheap, stable process and easy to master technology.3. China's Ministry of Housing and Urban-Rural Development stipulates that light energy-saving walls must be used for wall materials. With the large number of residential commercial houses, industrial parks and the transformation of old cities, the demand for light energy-saving walls is increasing day by day. There will be hundreds of billions of square meters of light energy-saving wall materials market demand.

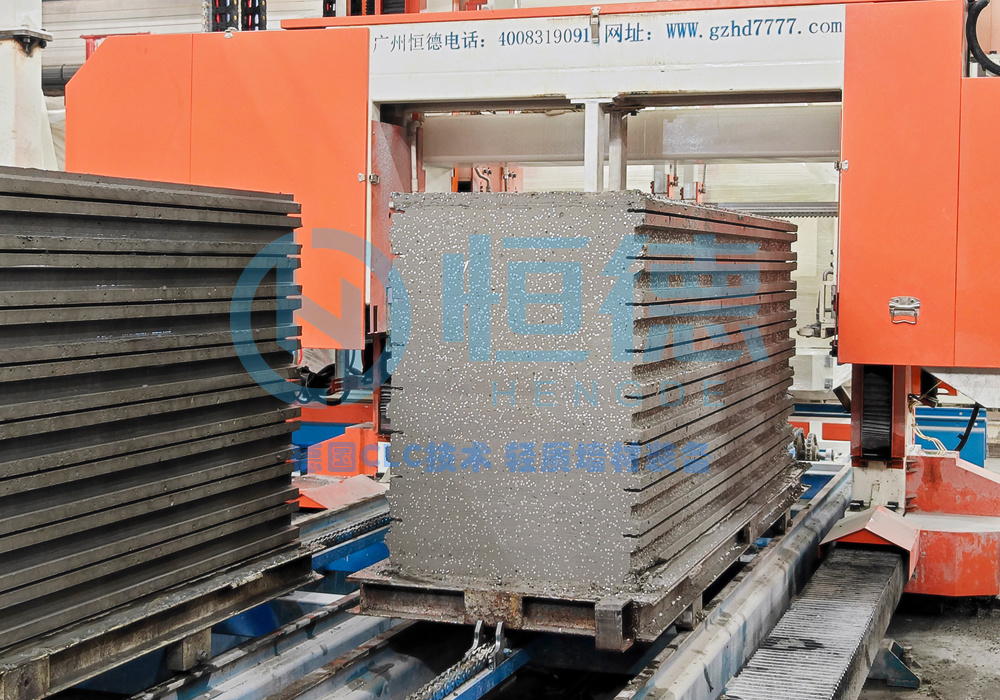

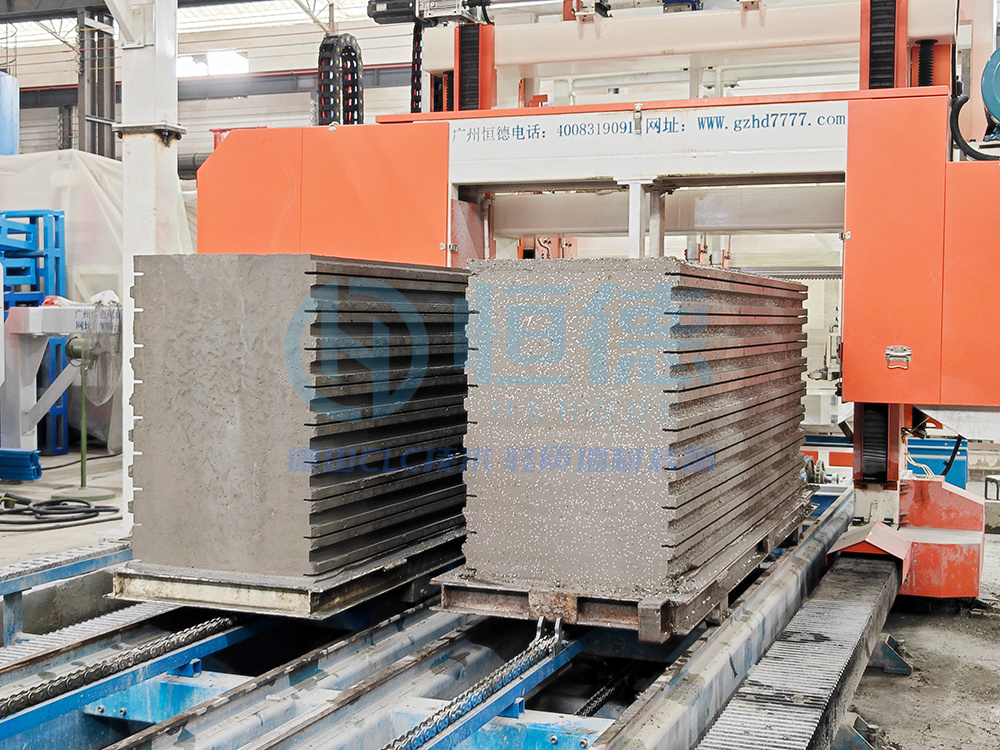

1. new EPS polystyrene particle wall board project advantages:1. The low-carbon, environmental protection, energy-saving, and waste-friendly projects supported by the government are in line with national industrial policies and enjoy multiple policy support such as tax exemption, subsidies for waste-friendly projects, and high-tech research and development funding.2. Industrial and agricultural solid waste (such as fly ash, coal gangue, quartz sand, tailings sand, rice bran, wheat straw, cotton stalk, sawdust, etc.) as raw materials, easy to buy, cheap, stable process and easy to master technology.3. China's Ministry of Housing and Urban-Rural Development stipulates that light energy-saving walls must be used for wall materials. With the large number of residential commercial houses, industrial parks and the transformation of old cities, the demand for light energy-saving walls is increasing day by day. There will be hundreds of billions of square meters of light energy-saving wall materials market demand. Introduction of 2. full-automatic EPS polystyrene particle wallboard equipment and technical characteristicsGuangzhou Hengde provides a complete set of partition board equipment production technology, formula, installation and technical training, planning and a series of services. The equipment has passed the quality appraisal and is a national building energy conservation and technology promotion unit.1, equipment investment advantages are obviousautomatic foaming cement partition board equipment (clc wallboard equipment) the total investment in building the factory is low, the period is short, the production cost is low, compared with alc wallboard products, the profit margin is large, the market competition is small.2. A variety of lightweight wallboard production processFlat formwork wallboard production line: it can produce cement foam partition board, ceramsite wallboard, GRC hollow wallboard, solid wallboard, etc.Vertical formwork wallboard production line: it can produce polystyrene particle wallboard, reinforced fiber wallboard or GRC cement mortar partition board, etc.

Introduction of 2. full-automatic EPS polystyrene particle wallboard equipment and technical characteristicsGuangzhou Hengde provides a complete set of partition board equipment production technology, formula, installation and technical training, planning and a series of services. The equipment has passed the quality appraisal and is a national building energy conservation and technology promotion unit.1, equipment investment advantages are obviousautomatic foaming cement partition board equipment (clc wallboard equipment) the total investment in building the factory is low, the period is short, the production cost is low, compared with alc wallboard products, the profit margin is large, the market competition is small.2. A variety of lightweight wallboard production processFlat formwork wallboard production line: it can produce cement foam partition board, ceramsite wallboard, GRC hollow wallboard, solid wallboard, etc.Vertical formwork wallboard production line: it can produce polystyrene particle wallboard, reinforced fiber wallboard or GRC cement mortar partition board, etc. 3. Proprietary wallboard rapid curing process-fast curing, high strength, no crackingDomestic new research and development of wallboard rapid maintenance kiln technology (Air energy conservation), under the condition of constant temperature and humidity, let the physical properties of the wallboard reach the best state, improve the strength of the wallboard, and there is no problem of cracking. Using this process, wallboard production is not affected by seasonal and climate change, and can be produced throughout the year.4. Partition wall board with reinforcement (high precision waterproof wall board)The production of this product is made of a group of flat molds, in which the steel mesh is a lightweight concrete plate made of reinforced material and cut and cured. The product is light, high strength, high precision, and is a side groove concave groove design, easy to quickly install after splicing to make the wall form a whole.

3. Proprietary wallboard rapid curing process-fast curing, high strength, no crackingDomestic new research and development of wallboard rapid maintenance kiln technology (Air energy conservation), under the condition of constant temperature and humidity, let the physical properties of the wallboard reach the best state, improve the strength of the wallboard, and there is no problem of cracking. Using this process, wallboard production is not affected by seasonal and climate change, and can be produced throughout the year.4. Partition wall board with reinforcement (high precision waterproof wall board)The production of this product is made of a group of flat molds, in which the steel mesh is a lightweight concrete plate made of reinforced material and cut and cured. The product is light, high strength, high precision, and is a side groove concave groove design, easy to quickly install after splicing to make the wall form a whole. 5, Cutting hollow wall panel production technologyUsing German imported technology and formula, the first production of a complete plate, and then cut into a single plate, and finally precise cutting slotting. This kind of wallboard has better strength than the traditional hollow wallboard on the market, is not easy to crack, and has better waterproof performance.6. Product specifications: General specifications are length: 2440mm, 3000mm, width: 610mm, thickness: 50, 75, 100, 125, 150mm, and can also be customized according to the specifications required by users.7. Application: Widely used in villas, buildings, industrial plants, warehouses, cold storage, the original building and other projects.

5, Cutting hollow wall panel production technologyUsing German imported technology and formula, the first production of a complete plate, and then cut into a single plate, and finally precise cutting slotting. This kind of wallboard has better strength than the traditional hollow wallboard on the market, is not easy to crack, and has better waterproof performance.6. Product specifications: General specifications are length: 2440mm, 3000mm, width: 610mm, thickness: 50, 75, 100, 125, 150mm, and can also be customized according to the specifications required by users.7. Application: Widely used in villas, buildings, industrial plants, warehouses, cold storage, the original building and other projects. 8、high precision high speed cutting saw: The new research and development of high-precision high-speed cutting saw system greatly improves the production capacity of the equipment, and the equipment has higher stability, strong durability and more convenient maintenance. The appearance of the product is neat, the size is standard, and there is no lack of edges and corners.9, Equipment price: different output, different configuration, different prices, Guangzhou HengdeEPS composite partition board equipmentCan be used in one machine, replacement of auxiliary equipment and formula can produce a variety of products, we will make configuration adjustments according to customer needs, the company project manager will provide you with equipment quotation, project report, picture data, etc.

8、high precision high speed cutting saw: The new research and development of high-precision high-speed cutting saw system greatly improves the production capacity of the equipment, and the equipment has higher stability, strong durability and more convenient maintenance. The appearance of the product is neat, the size is standard, and there is no lack of edges and corners.9, Equipment price: different output, different configuration, different prices, Guangzhou HengdeEPS composite partition board equipmentCan be used in one machine, replacement of auxiliary equipment and formula can produce a variety of products, we will make configuration adjustments according to customer needs, the company project manager will provide you with equipment quotation, project report, picture data, etc. 3.EPS polystyrene particle partition boardFeatures of the product1. Lightweight seismic resistanceCompared with clay solid bricks, lightweight wall panels are three to four times lighter and two to three times lighter than hollow blocks. It solves the problems of girders, columns and deep foundations. It is not only suitable for low-rise buildings, but also for high-rise buildings, light geology, beaches and other buildings. The frame connection has good seismic performance, the wall is light, and the wall collapses in the earthquake, which is not easy to cause casualties.2. Increase the use areaEPS polystyrene particle partition wall board is thin and saves space. Compared with traditional blocks, every 100 square meters of residential or commercial buildings can have an additional usable area of about 4-6 ㎡.3. Waterproof and moisture-proof, easy to decorateBecause it is an assembled construction, the body has a three-in-one structure, the plate and the plate are connected into a whole, the impact resistance is strong, the wall is anchored by the steel structure method, the wall is high in strength, and the spacer wall with large layer height and span can be made, and the overall seismic performance is many times higher than that of the ordinary masonry wall. The structure of the composite wall partition system is tightly waterproof and moisture-proof, and there will be no expansion due to moisture absorption, deformation, reduction of halogen return strength and condensation water droplets.4. Strong hanging forceIt can be directly nailed or hung with expansion bolts. The single-point hanging force is above 50kg. The surface of the wallboard is flat and smooth without dust. It can be directly pasted with ceramic tiles, wallpaper, wood veneer and other materials for finishing treatment.5. Low construction costProduct installation is simple and fast, free batch ash construction, low construction cost, the wall does not crack, sound insulation effect is better. Compared with clay brick, hollow block and ALC autoclaved aerated wall panel construction, the project cost is reduced by 20%.6. Fast construction and convenient installationEPS polystyrene particle wallboard is light in weight, easy to install and transport, wallboard can be sawed, nailed, drilled, and cut at will, making building patterns at will. The product has high strength and good flatness. It is constructed in a dry working environment and installed in a modular manner. It does not need plastering. After installation, it is equivalent to high-grade plastering and can be directly used for the next process such as painting and tiling. The three-person team has a daily construction volume of 100 ㎡, which is more than 3 times faster than plastering masonry such as ceramsite, and does not need 20 days of masonry shrinkage and settlement time, nor does it need 7 days of drying time for plastering the wall surface, thus greatly shortening the construction period.EPS polystyrene particle partition board Is a kind of energy-saving waste wall material, because the product does not use soil, no energy consumption, and in line with the "building materials of radionuclide limit" standard, belongs to the green environmental protection material. To meet the national building energy efficiency and wall material innovation and development requirements, to meet the national (GB6566-2001) standards, has been widely used, the use of wall panels in many wall materials, in order to be more economical, fast, convenient, to adapt to the rapid development of China's construction industry needs.

3.EPS polystyrene particle partition boardFeatures of the product1. Lightweight seismic resistanceCompared with clay solid bricks, lightweight wall panels are three to four times lighter and two to three times lighter than hollow blocks. It solves the problems of girders, columns and deep foundations. It is not only suitable for low-rise buildings, but also for high-rise buildings, light geology, beaches and other buildings. The frame connection has good seismic performance, the wall is light, and the wall collapses in the earthquake, which is not easy to cause casualties.2. Increase the use areaEPS polystyrene particle partition wall board is thin and saves space. Compared with traditional blocks, every 100 square meters of residential or commercial buildings can have an additional usable area of about 4-6 ㎡.3. Waterproof and moisture-proof, easy to decorateBecause it is an assembled construction, the body has a three-in-one structure, the plate and the plate are connected into a whole, the impact resistance is strong, the wall is anchored by the steel structure method, the wall is high in strength, and the spacer wall with large layer height and span can be made, and the overall seismic performance is many times higher than that of the ordinary masonry wall. The structure of the composite wall partition system is tightly waterproof and moisture-proof, and there will be no expansion due to moisture absorption, deformation, reduction of halogen return strength and condensation water droplets.4. Strong hanging forceIt can be directly nailed or hung with expansion bolts. The single-point hanging force is above 50kg. The surface of the wallboard is flat and smooth without dust. It can be directly pasted with ceramic tiles, wallpaper, wood veneer and other materials for finishing treatment.5. Low construction costProduct installation is simple and fast, free batch ash construction, low construction cost, the wall does not crack, sound insulation effect is better. Compared with clay brick, hollow block and ALC autoclaved aerated wall panel construction, the project cost is reduced by 20%.6. Fast construction and convenient installationEPS polystyrene particle wallboard is light in weight, easy to install and transport, wallboard can be sawed, nailed, drilled, and cut at will, making building patterns at will. The product has high strength and good flatness. It is constructed in a dry working environment and installed in a modular manner. It does not need plastering. After installation, it is equivalent to high-grade plastering and can be directly used for the next process such as painting and tiling. The three-person team has a daily construction volume of 100 ㎡, which is more than 3 times faster than plastering masonry such as ceramsite, and does not need 20 days of masonry shrinkage and settlement time, nor does it need 7 days of drying time for plastering the wall surface, thus greatly shortening the construction period.EPS polystyrene particle partition board Is a kind of energy-saving waste wall material, because the product does not use soil, no energy consumption, and in line with the "building materials of radionuclide limit" standard, belongs to the green environmental protection material. To meet the national building energy efficiency and wall material innovation and development requirements, to meet the national (GB6566-2001) standards, has been widely used, the use of wall panels in many wall materials, in order to be more economical, fast, convenient, to adapt to the rapid development of China's construction industry needs. Main technical parameters of 4. automatic EPS polystyrene particle production lineEPS polystyrene particle partition board equipment Can produce different thickness of the wall panel 800-3000 square/day. The specific input and output benefits need to determine the output, specifications, the degree of automation of production, etc., in order to make a more accurate analysis according to the specific situation.

Main technical parameters of 4. automatic EPS polystyrene particle production lineEPS polystyrene particle partition board equipment Can produce different thickness of the wall panel 800-3000 square/day. The specific input and output benefits need to determine the output, specifications, the degree of automation of production, etc., in order to make a more accurate analysis according to the specific situation.EPS polystyrene particle partition board main production raw materials: 425 cement, fly ash, construction waste, river sand, esp particles and other components, can be used locally. The company's project manager will help you analyze production costs, product profits, market prospects and plant investment planning according to your local raw material prices and market conditions.

Main production equipment, powerhouse, water and electricity:For cooperative customers, the company will provide customer planning plant support. When visiting Foshan factory, you can bring your plant drawings and the company will help you plan.(I) production plant and water and electricity requirementsProduction plant area: 20-60 meters wide, 80-200 meters long, 6 meters highProduct maintenance area: about 2000-8000 square meters (the above can be flexibly adjusted according to the output of the equipment)Water consumption: 80-500 tons/day; Electricity consumption: 200-800 kW (total power)Total factory area: 8-30 mu of land (flexibly adjusted according to sales volume)Raw materials for (II) production1. Cement: 425R Portland cement2.EPS polystyrene foam particles2. Fly ash raw ash (optional)3. Stone powder fine powder (optional)4. Sand (silt content ≤ 2% (optional)5. Slag powder fine powder (optional)6. Additives (provided by the company)

Our customers are all over the country, especially in cloud, expensive, Sichuan and other provinces. And exported to Central Asia, Southeast Asia, Africa and other regions of many countries. Customers who want to invest in projects abroad can contact our company.

Foaming core material: mixing ingredients, forming, curing, demolding, cutting and curing

Process flow surface material and compounding: mixing ingredients, roll forming, placing core material, roll forming, curing, demolding, curing and cutting

Welcome to make an appointment in advance to visit the company's Foshan factory site to see the equipment, see the production process, not afraid to compare with other manufacturers.

Related Products

online message

We will contact you as soon as possible