Formwork-free production line

Non removable insulation templates are widely used for interior walls, exterior walls, roof walls, walls, etc. Guangzhou Hengde's new generation of non removable template production line is fully automated, with stable production and high quality.

Product accessories:

Light partition board equipment

keyword: Formwork-free production line

- Product Description

-

The integrated board of building insulation structure, also known as the non-dismantling composite insulation outer formwork, refers to the composite of the insulation core material and cement mortar to realize factory prefabrication. As an exterior wall formwork, there is no need to dismantle the cast-in-place concrete. From the original four-sided formwork, cast-in-place concrete after the four-sided mold removal, the external wall is changed to the four-sided formwork mode, the three-sided demolition, the external formwork is not dismantled as the insulation layer and the wall is integrated, no longer need to do the external wall external insulation, and the external wall external insulation is structurally solved from the hollowing, falling off, fire, and secondary maintenance of the external wall external insulation, saving costs.

As a new type of wall material, the non-demolition insulation formwork (non-demolition insulation structure integrated board) is widely used in interior walls, exterior walls, roof walls, fences, etc., which can speed up construction, reduce labor intensity, shorten the construction period, reduce the project cost, and effectively improve the usable area of the building, which is the direction of wall reform.

As a new type of wall material, the non-demolition insulation formwork (non-demolition insulation structure integrated board) is widely used in interior walls, exterior walls, roof walls, fences, etc., which can speed up construction, reduce labor intensity, shorten the construction period, reduce the project cost, and effectively improve the usable area of the building, which is the direction of wall reform. 1. Introduction to the characteristics of automatic automatic dismantling and insulation formwork equipment and technical processGuangzhou Hengde provides a complete set of dismantling insulation formwork equipment production technology, formula, installation and technical training, planning and a series of services, using German imported CLC technology and equipment, a new generation of CLC dismantling insulation formwork equipment with low total investment, low production cost, compared with ALC wallboard products profit margins.1. A variety of lightweight wallboard production processesFlat mold wallboard production line: first produce cement foam core material, and then composite calcium silicate board and other panels to make cement foam lightweight partition board.Vertical formwork wall panel production line: it can produce polystyrene particles, reinforced fibers or GRC cement mortar and other material partition panels.CLC wallboard equipment production line: it can produce cement foam wallboard, ceramsite wallboard, ALC wallboard, high-precision waterproof wallboard, homogeneous board, prefabricated self-insulating wallboard and other boards.2. Proprietary wallboard rapid curing process - fast curing, high strength, no crackingThe new domestic research and development of rapid curing kiln technology (air energy curing) of wallboard makes the physical properties of wallboard reach the best state under the condition of constant temperature and humidity, improves the strength of wallboard, and there is no problem of cracking. With this process, the production of wall panels is not affected by the seasons and climate change and can be produced all year round.3. Partition wall board with steel barsThe production of this product is a lightweight concrete plate formed by pouring and forming a group of flat dies, in which the steel mesh sheet is a reinforcing material, and it is cut and cured. The product is lightweight, high-strength, high-precision, and is designed with side grooves and grooves, which is convenient for quick installation and splicing to make the wall form a whole.4. Cutting wallboard production technologyUsing the technology and formula imported from Germany, the complete plate is produced first, then cut into a single plate, and finally precision cutting and slotting. This kind of wall panel has better strength than traditional hollow wall panels on the market, is not easy to crack, and has better waterproof performance.5. Application field: widely used in villas, buildings, industrial plants, warehouses, cold storage, original buildings and other projects.

1. Introduction to the characteristics of automatic automatic dismantling and insulation formwork equipment and technical processGuangzhou Hengde provides a complete set of dismantling insulation formwork equipment production technology, formula, installation and technical training, planning and a series of services, using German imported CLC technology and equipment, a new generation of CLC dismantling insulation formwork equipment with low total investment, low production cost, compared with ALC wallboard products profit margins.1. A variety of lightweight wallboard production processesFlat mold wallboard production line: first produce cement foam core material, and then composite calcium silicate board and other panels to make cement foam lightweight partition board.Vertical formwork wall panel production line: it can produce polystyrene particles, reinforced fibers or GRC cement mortar and other material partition panels.CLC wallboard equipment production line: it can produce cement foam wallboard, ceramsite wallboard, ALC wallboard, high-precision waterproof wallboard, homogeneous board, prefabricated self-insulating wallboard and other boards.2. Proprietary wallboard rapid curing process - fast curing, high strength, no crackingThe new domestic research and development of rapid curing kiln technology (air energy curing) of wallboard makes the physical properties of wallboard reach the best state under the condition of constant temperature and humidity, improves the strength of wallboard, and there is no problem of cracking. With this process, the production of wall panels is not affected by the seasons and climate change and can be produced all year round.3. Partition wall board with steel barsThe production of this product is a lightweight concrete plate formed by pouring and forming a group of flat dies, in which the steel mesh sheet is a reinforcing material, and it is cut and cured. The product is lightweight, high-strength, high-precision, and is designed with side grooves and grooves, which is convenient for quick installation and splicing to make the wall form a whole.4. Cutting wallboard production technologyUsing the technology and formula imported from Germany, the complete plate is produced first, then cut into a single plate, and finally precision cutting and slotting. This kind of wall panel has better strength than traditional hollow wall panels on the market, is not easy to crack, and has better waterproof performance.5. Application field: widely used in villas, buildings, industrial plants, warehouses, cold storage, original buildings and other projects. 6. High-precision high-speed cutting saw: The newly developed high-precision high-speed cutting saw system greatly improves the production capacity of the equipment, and the equipment has higher stability, strong durability and more convenient maintenance. The appearance of the product is neat, the size is standard, and there are no missing edges and corners.7. Equipment price: different output, different configuration, price differences, Guangzhou Hengde insulation and dismantling integrated template equipment can be multi-purpose, replacing auxiliary equipment and formula can produce a variety of products, we will make configuration adjustments according to customer needs, the company's project manager will provide you with equipment quotations, project reports, picture information, etc.

6. High-precision high-speed cutting saw: The newly developed high-precision high-speed cutting saw system greatly improves the production capacity of the equipment, and the equipment has higher stability, strong durability and more convenient maintenance. The appearance of the product is neat, the size is standard, and there are no missing edges and corners.7. Equipment price: different output, different configuration, price differences, Guangzhou Hengde insulation and dismantling integrated template equipment can be multi-purpose, replacing auxiliary equipment and formula can produce a variety of products, we will make configuration adjustments according to customer needs, the company's project manager will provide you with equipment quotations, project reports, picture information, etc. Second, the product characteristics of the dismantling-free insulation template

Second, the product characteristics of the dismantling-free insulation template1. Thermal insulation: The core material of the integrated board of the thermal insulation structure is an insulation material, which has the characteristics of low thermal conductivity and good thermal insulation performance;

2. Sound absorption and noise reduction: it can prevent noise transmission and keep the room clean;

3. Fireproof and flame retardant: It has good fireproof and flame retardant performance, and is suitable for high-rise, ground floor, reconstruction and other buildings.

The concept of integrated technology of external wall demolition and insulation structure should meet three conditions:

First, the insulation of the building wall should be constructed synchronously with the structure, and at the same time, there should be a sufficient thickness of concrete or other inorganic material protective layer on the outside of the insulation layer;

Second, after construction, the structural insulation wall can meet the requirements of the current energy-saving standards without further insulation;

Third, it can realize the same life of building insulation and wall. Only when the above conditions are met can it be a building energy saving and structural integration technology.

Demolition insulation formwork is a kind of energy-saving and waste-free wall materials, because the product does not use soil, does not use energy consumption, and meets the "radionuclide limit of building materials" standard, belongs to the green environmental protection material. To meet the requirements of national building energy conservation and wall material innovation and development, to meet the national (GB6566-2001) standards, has been widely used, the use of partition panels in many wall materials, in order to be more economical, fast, convenient, to meet the needs of China's rapid development of the construction industry. 3. The main technical parameters of the automatic dismantling-free insulation formwork production lineThe production line of non-dismantling insulation formwork has a daily output of 1000-5000 square meters. The specific input and output benefits need to be determined first to determine the output, specifications, and degree of automation of production, so as to make a more accurate analysis according to the specific situation.

3. The main technical parameters of the automatic dismantling-free insulation formwork production lineThe production line of non-dismantling insulation formwork has a daily output of 1000-5000 square meters. The specific input and output benefits need to be determined first to determine the output, specifications, and degree of automation of production, so as to make a more accurate analysis according to the specific situation.

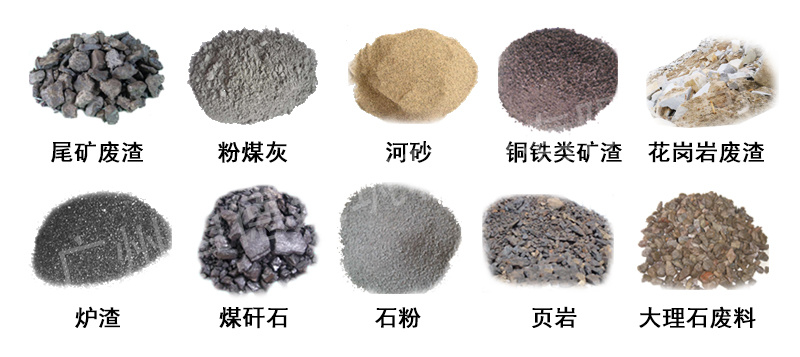

The main raw materials for the production of dismantle-free insulation formwork: 425 cement, fly ash, construction waste, river sand, plant fiber, etc., can be taken locally. The company's project manager will help you analyze the production cost, product profit, market prospect and investment plan according to your local raw material price and market situation.

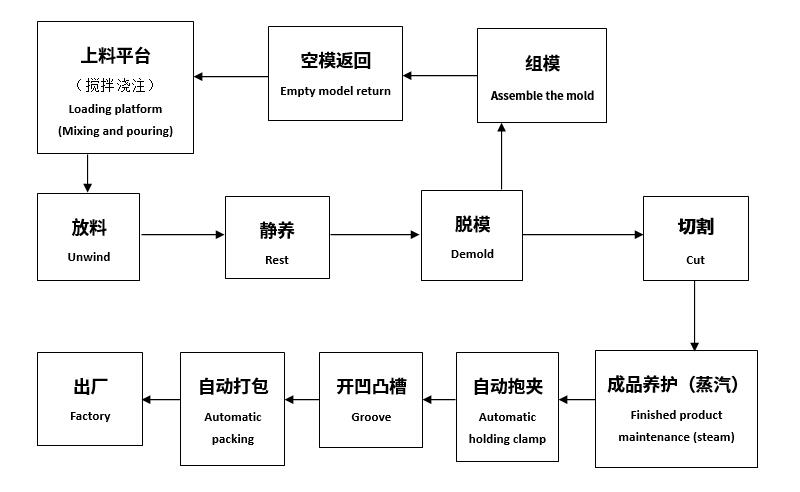

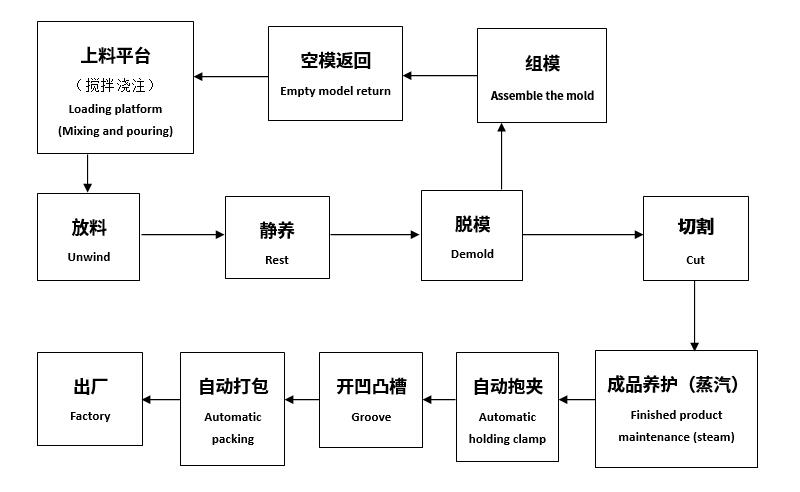

Main production equipment, plant, water and electricity:For cooperative customers, the company will provide customer planning plant support, you can bring your plant drawings when you visit the Foshan factory, and the company will help you plan.(1) Requirements for production plants and water and electricityProduction plant area: width 20-60 meters, length 80-200 meters, height from 6 metersProduct curing area: about 2000-8000 square meters (the above is flexibly adjusted according to the size of the equipment output)Water use: 80-500 tons/day; Electricity consumption: 200-800 kW (total power)Total factory area: 8-30 acres of land (flexible adjustment according to sales volume)(2) Production of raw materials1. Cement: 425R Portland cement2. Fly ash raw ash (optional)3. Stone powder fine powder (optional)4. Sand (mud content≤2% (optional)5. Slag powder fine powder (optional)6. Additives (provided by the company) Production process flow diagram

Production process flow diagram

Our customers are all over the country, especially in Yunnan, Guizhou, Sichuan and other provinces. And exported to many countries in Central Asia, Southeast Asia, Africa and other regions. Clients who want to invest in foreign projects can contact us.

Welcome to make an appointment in advance to visit the company's Foshan factory site to see the equipment and production process, and not afraid to compare with other manufacturers.

Related Products

online message

We will contact you as soon as possible