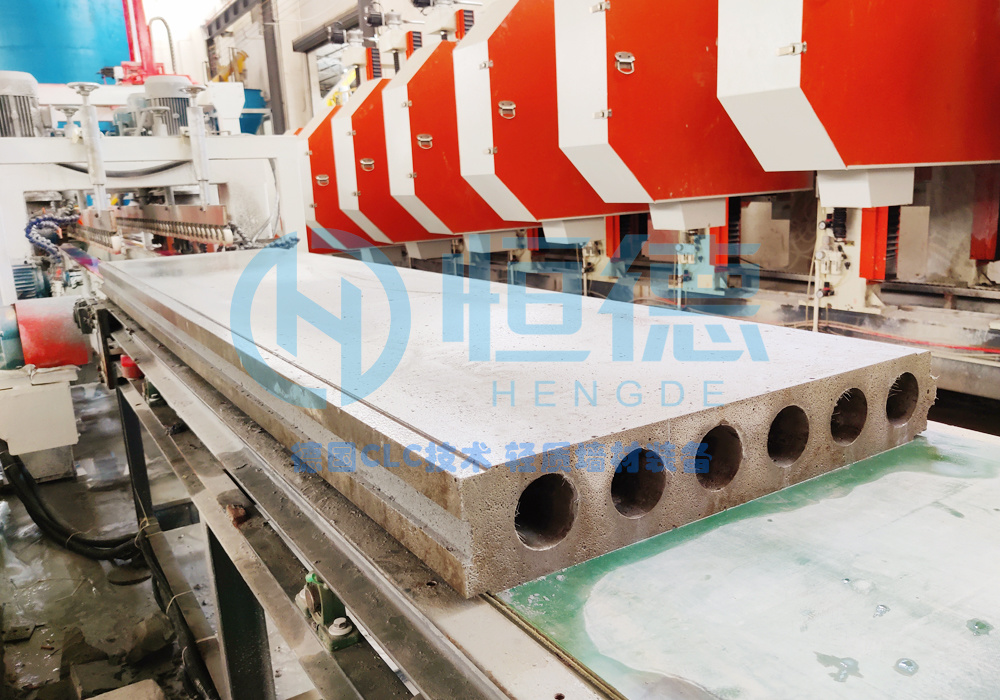

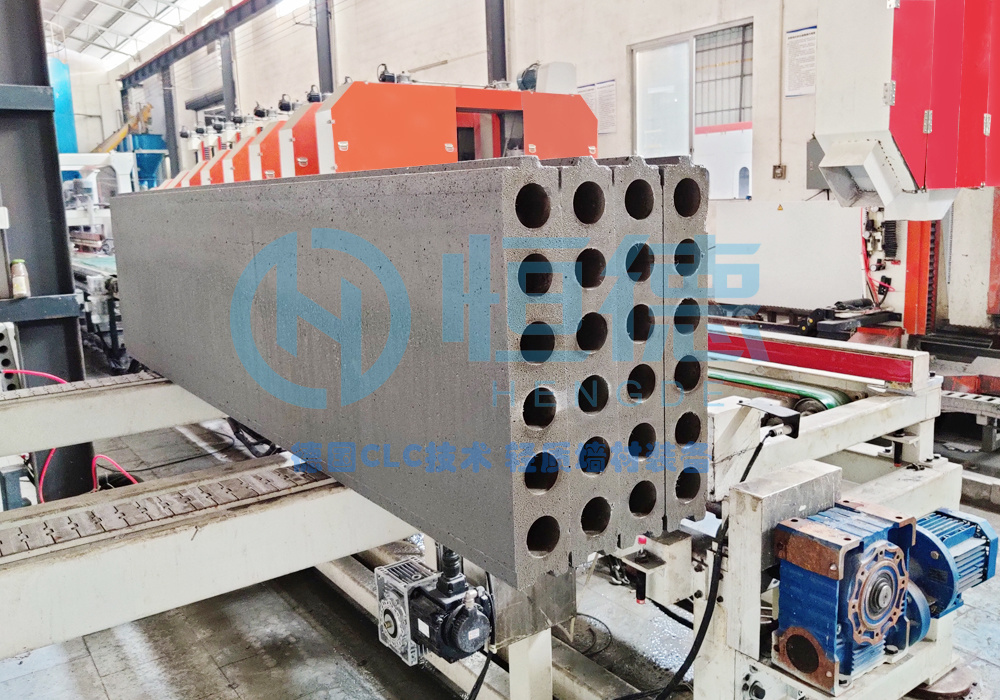

Cutting hollow wallboard production equipment

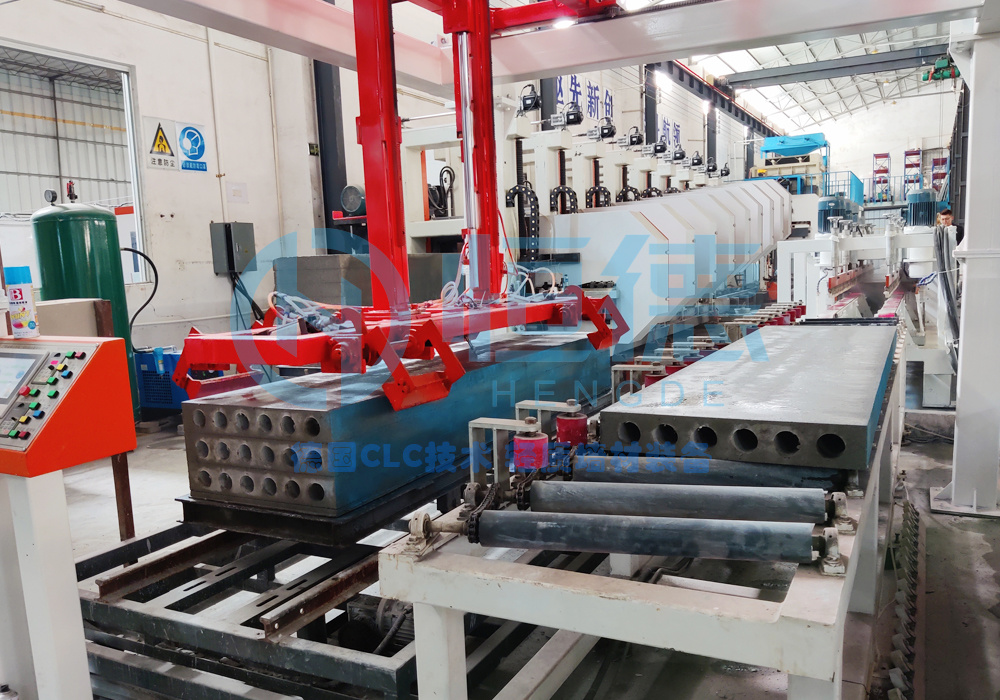

Guangzhou Hengde imported German CLC technology cutting hollow wallboard production line mainly includes six major systems: batching mixing, automatic grouting, mold turning, transportation system, finished product maintenance, demoulding and stacking system.

Product accessories:

keyword:

Light partition board equipment

keyword: Cutting hollow wallboard production equipment

Product classification:

- Product Description

-

1. automatic cutting type hollow wallboard equipment production line introduction:This set of automatic hollow wall panel production equipment is integrated with electric, hydraulic and mechanical.The hollow wallboard production line mainly includes six systems: batching mixing, automatic grouting, mold turning, transfer system, finished product maintenance, demoulding and stacking system.Using advanced industrial PLC control system, high-precision hydraulic components and compact mechanical structure, safe and stable operation can be realized.

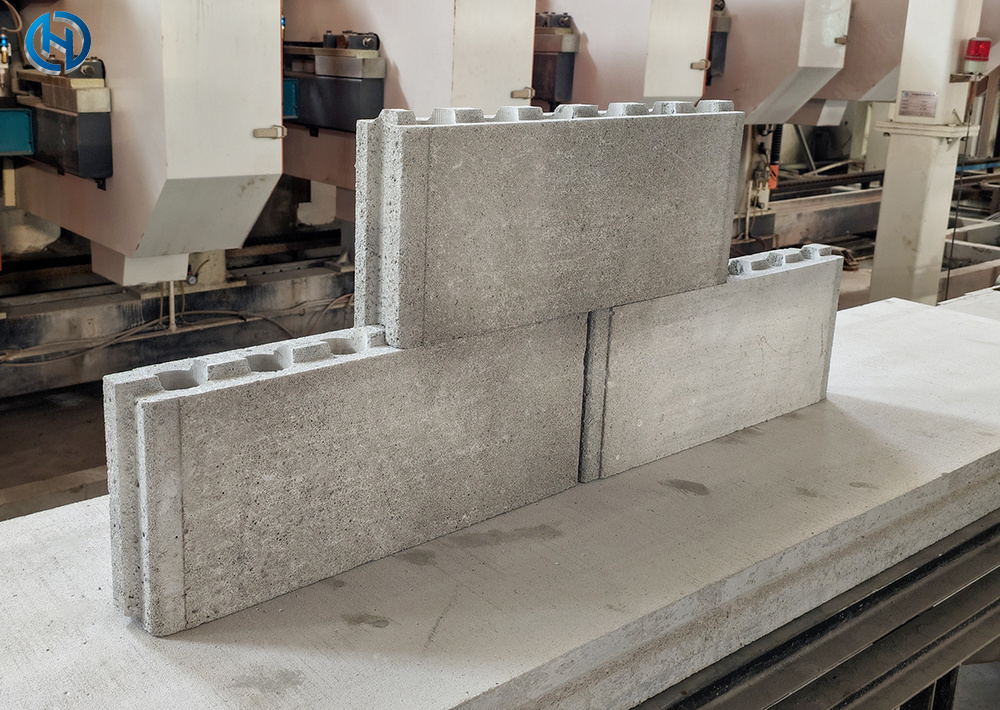

Introduction of 2. Automatic Cutting Hollow Wallboard Production LineAdvantages: high output, low investment ratio, large income, suitable for various scales of plate production.Uses: To be used in the production of solid wall panels, hollow wall panels and other lightweight board products.1. High degree of automationThe entire production line is automated to save labor costs and increase product profits. High space utilization, reduce land footprint and increase profit margins.2. High scientific and technological contentThe production line adopts advanced technology at home and abroad (German CLC wall material technology and equipment), and the production speed and product density can be adjusted and controlled.

Introduction of 2. Automatic Cutting Hollow Wallboard Production LineAdvantages: high output, low investment ratio, large income, suitable for various scales of plate production.Uses: To be used in the production of solid wall panels, hollow wall panels and other lightweight board products.1. High degree of automationThe entire production line is automated to save labor costs and increase product profits. High space utilization, reduce land footprint and increase profit margins.2. High scientific and technological contentThe production line adopts advanced technology at home and abroad (German CLC wall material technology and equipment), and the production speed and product density can be adjusted and controlled. 3. High production efficiency4, Horizontal hollow wall panel production process5. Production process of cutting hollow wallboard3. automatic cutting type hollow wallboard production line main equipment introduction:Including: storage equipment, feeding, metering equipment, fully automatic mixing equipment, pouring equipment, mold circulation equipment, wallboard molding mold car, plate equipment, etc.1. Material storage systemAccording to the scientific and reasonable supporting capacity, equipped with internal and external ladders, guardrails, bag dust removal, unloading valves, arch breaking devices, electronic position measuring device.2. Feeding systemWe use a screw conveyor, feeding speed, no dust, accurate measurement, and can be customized according to the conditions of the workshop length.3. Metering and weighing systemIncluding liquid weighing and powder weighing two parts.4. Mixing system5. Automatic cleaning system6. Molding Mold Car7. Automatic extraction and insertion system8, PLC electric control system9. Automatic plate-out system10. Package operation systemLightweight wallboard is a new type of green, energy-saving and environmental protection wall material products. It can be used as a partition wall for high-rise buildings, as well as the exterior walls and partition walls of steel structure prefabricated houses and villas. Its birth replaced the traditional red brick and aerated block, which can fully meet the requirements of modern buildings for walls.Lightweight wallboard has the advantages of light weight, thin thickness, high strength, heat and sound insulation, waterproof, moisture-proof, earthquake-proof, heat insulation, etc., and can be nailed, sawed, slotted, convenient for construction site installation. It can reduce the overall weight of the building, increase the available space, and save a lot of construction costs.Cutting hollow wall panel project investment conditions:(I) production plant and water and electricity requirementsProduction plant area: 20-60 meters wide, 80-200 meters long, 6 meters highProduct maintenance area: about 2000-8000 square meters (the above can be flexibly adjusted according to the output of the equipment)Water consumption: 80-500 tons/day; Electricity consumption: 200-800 kW (total power)Total factory area: 8-30 mu of land (flexibly adjusted according to sales volume)

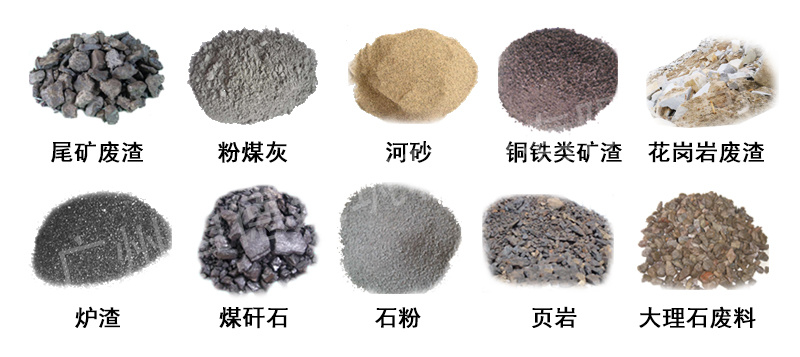

3. High production efficiency4, Horizontal hollow wall panel production process5. Production process of cutting hollow wallboard3. automatic cutting type hollow wallboard production line main equipment introduction:Including: storage equipment, feeding, metering equipment, fully automatic mixing equipment, pouring equipment, mold circulation equipment, wallboard molding mold car, plate equipment, etc.1. Material storage systemAccording to the scientific and reasonable supporting capacity, equipped with internal and external ladders, guardrails, bag dust removal, unloading valves, arch breaking devices, electronic position measuring device.2. Feeding systemWe use a screw conveyor, feeding speed, no dust, accurate measurement, and can be customized according to the conditions of the workshop length.3. Metering and weighing systemIncluding liquid weighing and powder weighing two parts.4. Mixing system5. Automatic cleaning system6. Molding Mold Car7. Automatic extraction and insertion system8, PLC electric control system9. Automatic plate-out system10. Package operation systemLightweight wallboard is a new type of green, energy-saving and environmental protection wall material products. It can be used as a partition wall for high-rise buildings, as well as the exterior walls and partition walls of steel structure prefabricated houses and villas. Its birth replaced the traditional red brick and aerated block, which can fully meet the requirements of modern buildings for walls.Lightweight wallboard has the advantages of light weight, thin thickness, high strength, heat and sound insulation, waterproof, moisture-proof, earthquake-proof, heat insulation, etc., and can be nailed, sawed, slotted, convenient for construction site installation. It can reduce the overall weight of the building, increase the available space, and save a lot of construction costs.Cutting hollow wall panel project investment conditions:(I) production plant and water and electricity requirementsProduction plant area: 20-60 meters wide, 80-200 meters long, 6 meters highProduct maintenance area: about 2000-8000 square meters (the above can be flexibly adjusted according to the output of the equipment)Water consumption: 80-500 tons/day; Electricity consumption: 200-800 kW (total power)Total factory area: 8-30 mu of land (flexibly adjusted according to sales volume) Raw material requirements for (II) production1. Cement: 425R Portland cement (required); 2. Fly ash raw ash (optional); 3. Stone powder fine powder (optional);4. Sand (silt content ≤ 2% (optional); 5. Slag powder fine powder (optional);6. Additives (provided by the company)

Raw material requirements for (II) production1. Cement: 425R Portland cement (required); 2. Fly ash raw ash (optional); 3. Stone powder fine powder (optional);4. Sand (silt content ≤ 2% (optional); 5. Slag powder fine powder (optional);6. Additives (provided by the company) About equipment price:Due to different output and different configurations, the price of the equipment varies. Guangzhou Hengde green wall material production equipment can be used in one machine for multiple purposes. Changing auxiliary equipment and formula can produce a variety of products. We will make configuration adjustments according to customer's needs. The company's project manager will provide you with quotations, project reports, picture materials, etc. for various hollow wall panel equipment.Welcome to make an appointment in advance (hotline: 400-831-9091) to visit our Foshan factory to see the hollow wallboard equipment and the production process. We are not afraid to compare with other manufacturers.

About equipment price:Due to different output and different configurations, the price of the equipment varies. Guangzhou Hengde green wall material production equipment can be used in one machine for multiple purposes. Changing auxiliary equipment and formula can produce a variety of products. We will make configuration adjustments according to customer's needs. The company's project manager will provide you with quotations, project reports, picture materials, etc. for various hollow wall panel equipment.Welcome to make an appointment in advance (hotline: 400-831-9091) to visit our Foshan factory to see the hollow wallboard equipment and the production process. We are not afraid to compare with other manufacturers.

Related Products

online message

We will contact you as soon as possible