Light ceramsite partition board equipment

Guangzhou Hengde lightweight ceramsite partition board equipment is a lightweight high-strength ceramsite, fiber, cement, fly ash and water and other raw materials, through the cement foaming process molding cutting and maintenance of lightweight wallboard.

Product accessories:

keyword: Light ceramsite partition board equipment

- Product Description

-

In order to protect arable land, save energy, and maintain the sustainable and healthy development of our country, the state issued a document prohibiting the use of solid clay bricks. The State Council issued a series of measures to promote the innovation of wall materials and promote energy-saving buildings, and develop new types of wall materials that save energy, land and waste. material.Lightweight ceramsite partition board It is a lightweight wallboard with high strength ceramsite, engineering fiber, cement and fly ash as raw materials, formed and cut by Guangzhou Hengde special cement foaming process and maintained.Light ceramsite partition wall board has any other wall materials can not be compared with the advantages, such as high strength, smooth surface, good overall performance, corrosion resistance, small shrinkage, anti-aging performance, fire prevention, waterproof, sound insulation, heat insulation, thermal insulation and installation and routing convenient, can be chiseled, can be cut, can be nailed, impact resistance.

1. new ceramsite partition board project advantages:1. The low-carbon, environmental protection, energy-saving, and waste-friendly projects supported by the government are in line with national industrial policies and enjoy multiple policy support such as tax exemption, subsidies for waste-friendly projects, and high-tech research and development funding.2. Ceramsite and solid waste (such as fly ash, coal gangue, quartz sand, tailings sand, etc.) as raw materials, easy to buy, cheap, stable process and easy to master technology.3. China's Ministry of Housing and Urban-Rural Development stipulates that light energy-saving walls must be used for wall materials. With the large number of residential commercial houses, industrial parks and the transformation of old cities, the demand for light energy-saving walls is increasing day by day. There will be hundreds of billions of square meters of light energy-saving wall materials market demand.

1. new ceramsite partition board project advantages:1. The low-carbon, environmental protection, energy-saving, and waste-friendly projects supported by the government are in line with national industrial policies and enjoy multiple policy support such as tax exemption, subsidies for waste-friendly projects, and high-tech research and development funding.2. Ceramsite and solid waste (such as fly ash, coal gangue, quartz sand, tailings sand, etc.) as raw materials, easy to buy, cheap, stable process and easy to master technology.3. China's Ministry of Housing and Urban-Rural Development stipulates that light energy-saving walls must be used for wall materials. With the large number of residential commercial houses, industrial parks and the transformation of old cities, the demand for light energy-saving walls is increasing day by day. There will be hundreds of billions of square meters of light energy-saving wall materials market demand. Introduction of full-automatic light ceramsite partition board equipment and technical characteristics of 2.Guangzhou Hengde provides a complete set of light ceramsite wallboard production technology, formula, installation and technical training, planning and a series of services. The equipment has passed the quality appraisal and is a national building energy conservation and technology promotion unit.1, Seamless butt wall panel production processnew type Light ceramsite wall panel equipment Seamless docking technology is adopted to reduce the size of the wallboard, and the docking installation between the partitions is carried out. By pouring concrete (cement) or adding steel bars to fix, the problem of cracking and damage of the wallboard can be completely solved and the service life of the material can be improved. The installation speed is 2 times higher than that of ordinary wallboard.2, CLC foam concrete wall panel production processCLC wallboard production line: can produce pure concrete wallboard,Ceramsite wallboard, AlC wall panels, etc.High precision waterproof wallboard production line: Hengde special production process and formula, can produce high precision, waterproof not cracking, easy to install new wallboard.

Introduction of full-automatic light ceramsite partition board equipment and technical characteristics of 2.Guangzhou Hengde provides a complete set of light ceramsite wallboard production technology, formula, installation and technical training, planning and a series of services. The equipment has passed the quality appraisal and is a national building energy conservation and technology promotion unit.1, Seamless butt wall panel production processnew type Light ceramsite wall panel equipment Seamless docking technology is adopted to reduce the size of the wallboard, and the docking installation between the partitions is carried out. By pouring concrete (cement) or adding steel bars to fix, the problem of cracking and damage of the wallboard can be completely solved and the service life of the material can be improved. The installation speed is 2 times higher than that of ordinary wallboard.2, CLC foam concrete wall panel production processCLC wallboard production line: can produce pure concrete wallboard,Ceramsite wallboard, AlC wall panels, etc.High precision waterproof wallboard production line: Hengde special production process and formula, can produce high precision, waterproof not cracking, easy to install new wallboard. 3. Rapid maintenance technology of wallboard-fast maintenance, high strength and no crackingDomestic new research and development of wallboard rapid curing kiln technology (air energy), under the condition of constant temperature and humidity, the physical properties of the wallboard to achieve the best state, improve the strength of the wallboard, there is no problem of cracking. Using this process, wallboard production is not affected by seasonal and climate change, and can be produced throughout the year.

3. Rapid maintenance technology of wallboard-fast maintenance, high strength and no crackingDomestic new research and development of wallboard rapid curing kiln technology (air energy), under the condition of constant temperature and humidity, the physical properties of the wallboard to achieve the best state, improve the strength of the wallboard, there is no problem of cracking. Using this process, wallboard production is not affected by seasonal and climate change, and can be produced throughout the year. 4. Product specifications: General specifications are length: 2440mm, 3000mm, width: 610mm, thickness: 50, 75, 100, 125, 150mm, and can also be customized according to the specifications required by users.5. Scope of application: It is applicable to non-load-bearing walls of multi-and high-rise buildings, kitchen and toilet projects, restaurants, karaoke halls, hotels, residential buildings and other decoration for exterior wall projects, and internal partition wall projects of old house renovation projects.

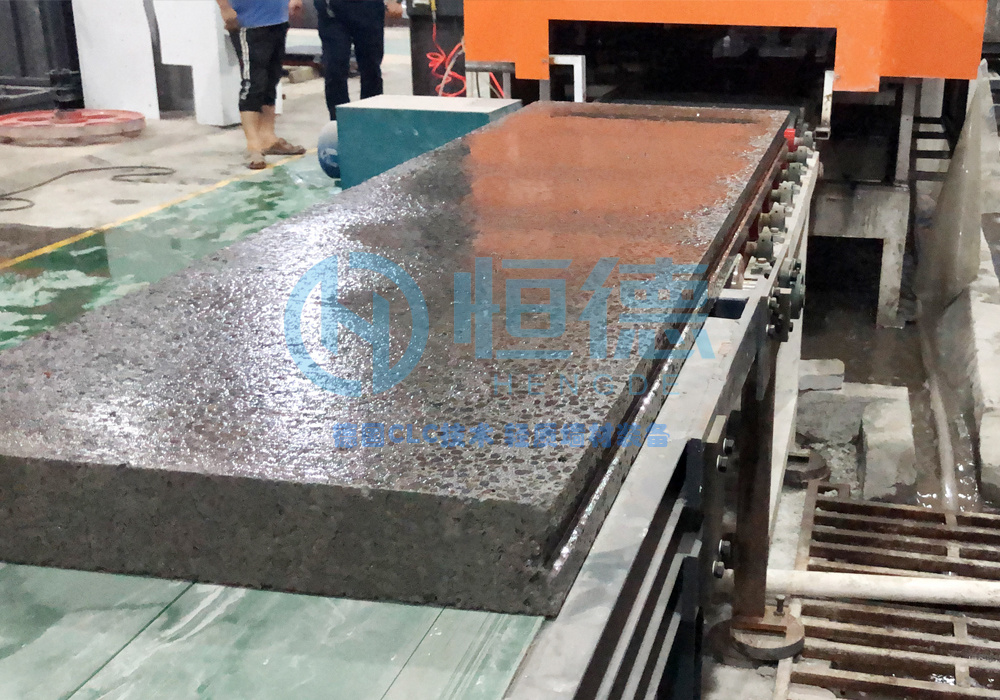

4. Product specifications: General specifications are length: 2440mm, 3000mm, width: 610mm, thickness: 50, 75, 100, 125, 150mm, and can also be customized according to the specifications required by users.5. Scope of application: It is applicable to non-load-bearing walls of multi-and high-rise buildings, kitchen and toilet projects, restaurants, karaoke halls, hotels, residential buildings and other decoration for exterior wall projects, and internal partition wall projects of old house renovation projects. 6、high precision high speed cutting saw:The new research and development of high-precision high-speed cutting saw system greatly improves the production capacity of the equipment, and the equipment has higher stability, strong durability and more convenient maintenance. The appearance of the product is neat, the size is standard, and there is no lack of edges and corners.7, equipment price: different production, different configuration, the price is different, Guangzhou Hengde.Ceramsite foam partition board equipmentCan be used in one machine, replacement of auxiliary equipment and formula can produce a variety of products, we will make configuration adjustments according to customer needs, the company project manager will provide you with equipment quotation, project report, picture data, etc.

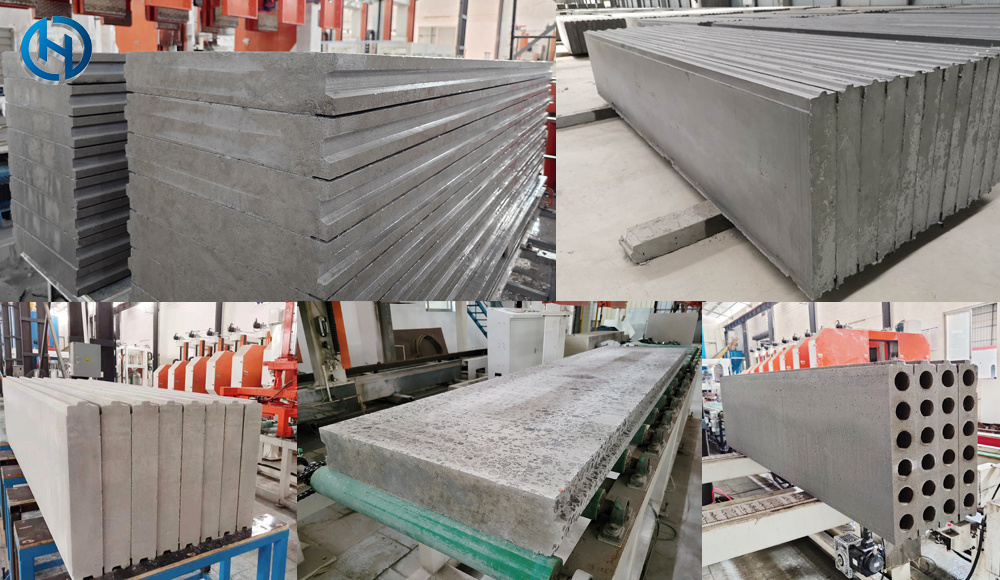

6、high precision high speed cutting saw:The new research and development of high-precision high-speed cutting saw system greatly improves the production capacity of the equipment, and the equipment has higher stability, strong durability and more convenient maintenance. The appearance of the product is neat, the size is standard, and there is no lack of edges and corners.7, equipment price: different production, different configuration, the price is different, Guangzhou Hengde.Ceramsite foam partition board equipmentCan be used in one machine, replacement of auxiliary equipment and formula can produce a variety of products, we will make configuration adjustments according to customer needs, the company project manager will provide you with equipment quotation, project report, picture data, etc. Product features of 3. lightweight ceramsite partition board1. Light weight: The weight of the wall panel per square meter is less than 70kg, which is equivalent to 1/4 of the solid 24 brick wall, which greatly reduces the weight of the engineering foundation.2. Thin wall: The performance of 90mm thick wall panel is equivalent to that of 240mm brick wall, which can expand the usable area of the house by 10% ~ 13%.3. Sound insulation and sound absorption: the sound insulation rate is more than 48db; and because the honeycomb structure of ceramsite and mortar contain rich and uniform small bubbles, the sound absorption effect is good.4. Various mechanical and physical indicators: high compressive strength, bending load, impact resistance, sound insulation, heat preservation, fire prevention, and dry shrinkage indicators all meet the requirements of industry standards.5. Smooth board surface: two plastering processes are eliminated, and the wall surface meets the painting standard and quality requirements.6. Simple and quick installation: dry operation, nail, saw, drill, easy cutting, convenient pipe embedding and routing, and quick installation.7, improve the construction speed: the wall can be directly approved putty, brush pulp or wall paper, ceramic tiles and other decorative materials, speed up the construction speed of 3 to 5 times.8. Unique structure: the two sides of the board are connected by high-strength cement glue, which makes the whole wall form a whole, improves the impact resistance and seismic effect of the wall, and solves the problem of wall panel cracks.9. High strength: hanging> 1000N, TV, air conditioner, range hood, water heater, wash basin, etc.10. Energy saving and environmental protection: replace clay brick, save land, environmental protection and waste, green building materials.Main technical parameters of 4. automatic lightweight ceramsite partition board production lineLight ceramsite partition board production line Nissan 150 cubic lightweight foamed ceramsite material, can be cut into different thickness of the wallboard 800-2500 square. The specific input and output benefits need to determine the output, specifications, the degree of automation of production, etc., in order to make a more accurate analysis according to the specific situation.

Product features of 3. lightweight ceramsite partition board1. Light weight: The weight of the wall panel per square meter is less than 70kg, which is equivalent to 1/4 of the solid 24 brick wall, which greatly reduces the weight of the engineering foundation.2. Thin wall: The performance of 90mm thick wall panel is equivalent to that of 240mm brick wall, which can expand the usable area of the house by 10% ~ 13%.3. Sound insulation and sound absorption: the sound insulation rate is more than 48db; and because the honeycomb structure of ceramsite and mortar contain rich and uniform small bubbles, the sound absorption effect is good.4. Various mechanical and physical indicators: high compressive strength, bending load, impact resistance, sound insulation, heat preservation, fire prevention, and dry shrinkage indicators all meet the requirements of industry standards.5. Smooth board surface: two plastering processes are eliminated, and the wall surface meets the painting standard and quality requirements.6. Simple and quick installation: dry operation, nail, saw, drill, easy cutting, convenient pipe embedding and routing, and quick installation.7, improve the construction speed: the wall can be directly approved putty, brush pulp or wall paper, ceramic tiles and other decorative materials, speed up the construction speed of 3 to 5 times.8. Unique structure: the two sides of the board are connected by high-strength cement glue, which makes the whole wall form a whole, improves the impact resistance and seismic effect of the wall, and solves the problem of wall panel cracks.9. High strength: hanging> 1000N, TV, air conditioner, range hood, water heater, wash basin, etc.10. Energy saving and environmental protection: replace clay brick, save land, environmental protection and waste, green building materials.Main technical parameters of 4. automatic lightweight ceramsite partition board production lineLight ceramsite partition board production line Nissan 150 cubic lightweight foamed ceramsite material, can be cut into different thickness of the wallboard 800-2500 square. The specific input and output benefits need to determine the output, specifications, the degree of automation of production, etc., in order to make a more accurate analysis according to the specific situation.

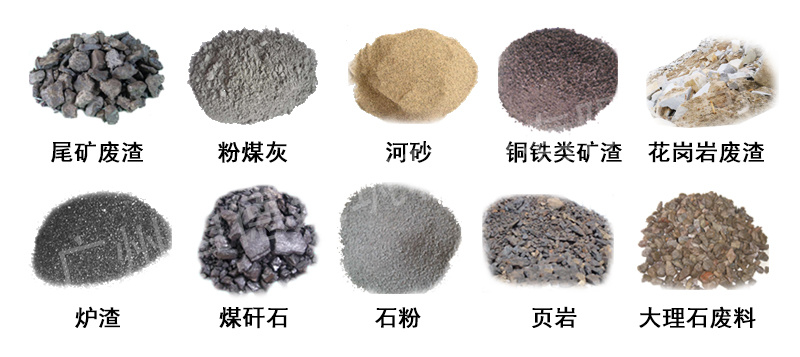

Lightweight ceramsite partition board The main production of raw materials: 425 cement, selected ceramsite, fly ash, construction waste, river sand, plant fiber and other components, can be used locally. The company's project manager will help you analyze production costs, product profits, market prospects and plant investment planning according to your local raw material prices and market conditions.

Main production equipment, powerhouse, water and electricityFor cooperative customers, the company will provide customer planning plant support. When visiting Foshan factory, you can bring your plant drawings and the company will help you plan.(I) production plant and water and electricity requirementsProduction plant area: 20-60 meters wide, 80-200 meters long, 6 meters highProduct maintenance area: about 2000-8000 square meters (the above can be flexibly adjusted according to the output of the equipment)Water consumption: 80-500 tons/day; Electricity consumption: 200-800 kW (total power)Total factory area: 8-30 mu of land (flexibly adjusted according to sales volume)Raw materials for (II) production1. Cement: 425R Portland cement2. Selected Ceramsite3. Fly ash and stone powder (optional)4. Sand (silt content ≤ 2% (optional)5. Slag powder fine powder (optional)6. Additives (provided by the company)

Our customers are all over the country, especially in cloud, expensive, Sichuan and other provinces. And exported to Central Asia, Southeast Asia, Africa and other regions of many countries. Customers who want to invest in projects abroad can contact our company.

Foaming core material: mixing ingredients, forming, curing, demolding, cutting and curing

Process flow surface material and compounding: mixing ingredients, roll forming, placing core material, roll forming, curing, demolding, curing and cutting

Welcome to make an appointment in advance to visit the company's Foshan factory site to see the equipment, see the production process, not afraid to compare with other manufacturers.

Pre: Ceramsite wallboard cutting machine

Next: None

Related Products

online message

We will contact you as soon as possible