-

What are the domestic technology and equipment of self-insulation block production equipment manufacturers? See Guangzhou Hengde

What are the domestic self-insulation block production equipment manufacturers? How to choose? Equipment manufacturers all over the country, mainly concentrated in several provinces and cities in North China, each manufacturer's equipment prices are not the same, the process is basically similar.

In recent years, the more popular method of thermal insulation is the self-insulation block system. Most types of civil buildings are generally wall insulation blocks, which have very good thermal insulation effects and meet relevant national industry standards. High-strength insulation blocks can prevent deformation, the material is relatively light, and can be used with the system software material attached to the wall surface, without the actual impact of the seismic level of the building is not easily damaged. The composite self-insulating block can be laser cut at will to make different shape designs, thus enriching the building facade design of engineering buildings. In North China, the thickness is generally suitable for 5-10cm, and it is not easy to change the total construction area.

Green is very important,Self-insulating blockIn particular, the use of fly ash, tailings and other raw materials can not only comprehensively utilize industrial waste residue, but also recycle all waste materials in the production process, control environmental pollution, do not destroy cultivated land, and completely green and environmentally friendly. It can also meet the building standard requirements of 65% of the building energy efficiency proposed by the Ministry of Construction, and can promote the renovation of wall materials. While the industrial waste residue fly ash that brings serious harm can be comprehensively treated and utilized, it can enjoy many preferential policies such as wall reform and taxation, so as to obtain better environmental, social and economic benefits, and has broad market development prospects.

What are the domestic self-insulation block production equipment manufacturers, technology and equipment or visit Guangzhou Hengde, contrast to contrast, and other manufacturers are really different. Guangzhou Hengde focuses on the research and development and manufacturing of green wall materials and equipment. The self-insulation block equipment has mature technology, stable and reliable formula and smooth operation of the production line. Guangzhou Hengde relies on scientific and technological innovation, optimizes product structure, expands business areas, always focuses on the level of the industry, and speeds up the pace of product upgrading.

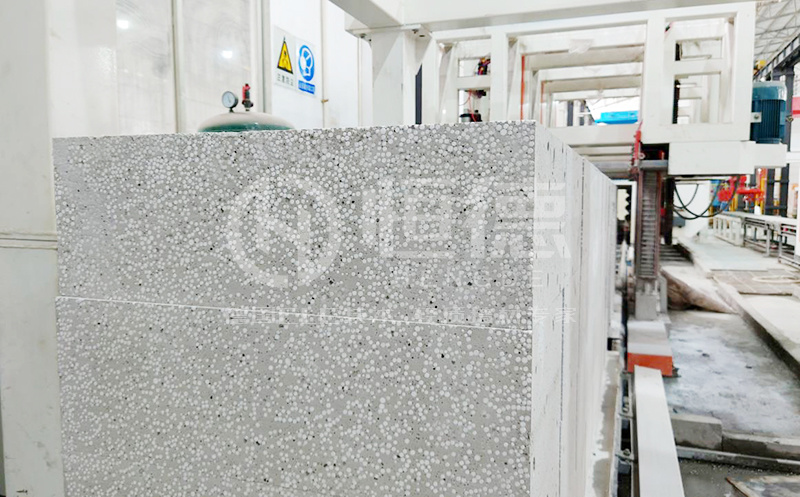

What are the domestic self-insulation block production equipment manufacturersEquipment manufacturers all over the country have, mainly concentrated in several provinces and cities in North China, each manufacturer's equipment prices are not the same, the process is basically similar. The choice of manufacturers still depends on the quality of equipment and the advanced level of production technology, which is the key to the success of production and investment. Guangzhou Hengde company is a professional manufacturer of green wall materials and equipment enterprises, research and development of a new generation of self-insulation block production equipment, using German LUCA imported technology and equipment, and has many yearsSelf-insulation block production lineManufacturing experience. Equipment production raw materials mainly use industrial waste. Fly ash, slag, ceramsite, etc. have reached more than 80%, truly turning waste into treasure. The production process does not produce waste water, waste gas, waste, etc., is regarded as a real low-carbon, green building materials. Homogeneous self-insulation block contains the characteristics of polystyrene foam particles and foam concrete. Its insulation and wall are "two in one". Homogeneous self-insulation block is composed of main block and polystyrene particles. Homogeneous self-insulation block is made by mixing and casting and cutting cement foaming process, with good heat insulation performance, strong bonding force, good impermeability and crack resistance. Self-insulation block products have the advantages of self-insulation, sound insulation, fire resistance, light weight, load-bearing, simple construction, low construction cost, low energy consumption and environmental protection, and have great market application prospects.