22

2025

-

04

Albanian client and Hengde reach cooperation on lightweight brick equipment, realizing transnational intelligent manufacturing and customized future

On April 21, 2025, an Albanian customer, after learning about the company through online search, made a special trip for an on-site visit. The customer was impressed by the factory's equipment and professional services upon their first visit, immediately deciding to cooperate and successfully signing a contract for the purchase of lightweight brick equipment.

On April 21, 2025, an Albanian customer, after learning about the company through online search, made a special trip for an on-site visit. Impressed by the factory's equipment and professional services on their first visit, the customer immediately decided to cooperate and successfully signed a contract for the purchase of lightweight brick equipment.

Albania: A New Frontier for Building Material Demand in the Balkans

In recent years, Albania's economy has steadily grown. In 2023, the GDP reached US\$23.3 billion, with a per capita GDP of approximately US\$8,800. With the acceleration of urbanization, urban construction projects are constantly emerging, and the construction of infrastructure such as commercial centers and residential areas is booming. This development has led to a continuous increase in the demand for lightweight and environmentally friendly building materials, opening up vast space for the building materials market.

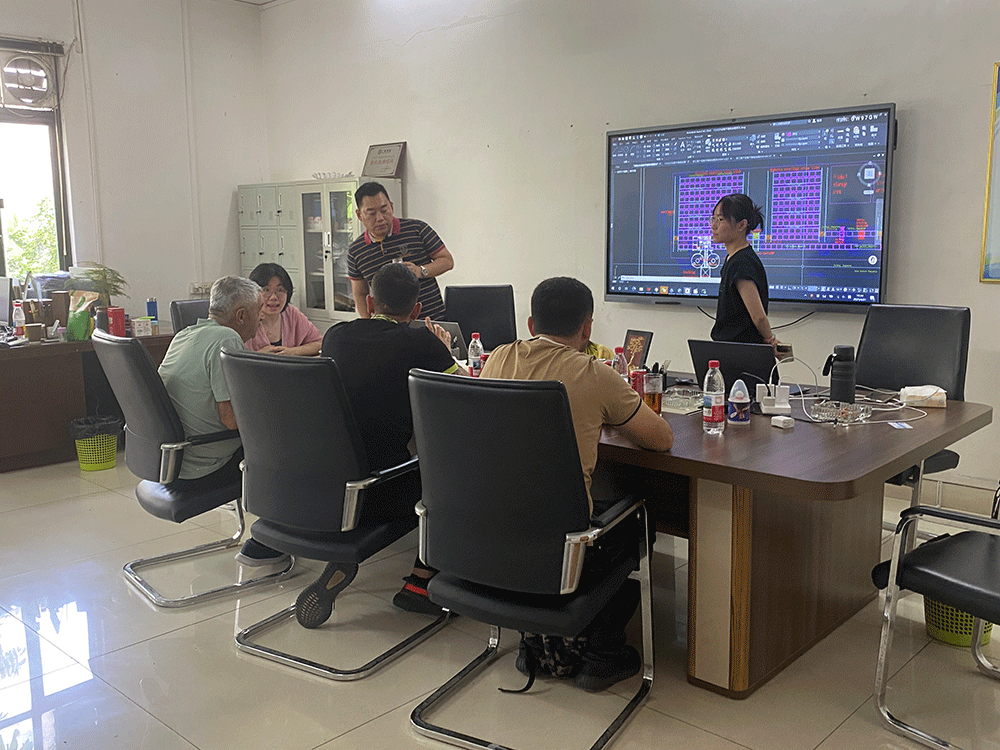

On-site Witness: Industry Benchmark Strength Conquers Customers

The moment the customer entered the factory workshop, they were captivated by the busy and operating equipment. The Hengde team immediately started the equipment demonstration. The embryo stacking machine, stacking machine, and demolding machine operated in an orderly manner. The smooth cutting of the Hengde cutting machine kept the customer engrossed. When the world's largest cutting system started, its stable operation and cutting accuracy of less than 1 mm impressed the customer. Upon learning that the industry standard for this cutting system was drafted with the participation of Mr. Shao, the head of Guangzhou Hengde, the customer couldn't hide their excitement: "It's so fortunate to be able to cooperate with a top team in the industry!" Overwhelmed with excitement, the customer immediately expressed their wish to purchase the equipment demonstrated on-site to start production as quickly as possible.

In the subsequent discussions, both parties quickly moved to the core issues. The customer clearly stated their initial plan to purchase a block production line and hoped that the equipment could be upgraded for wall panel production later. The Guangzhou Hengde team promised on-site that the equipment would have upgrade interfaces for seamless integration with wall panel production needs. Regarding the customer's confusion about the PLC controller not being included in the equipment list, the technicians explained in detail that it needs to be customized according to production needs and promised to provide a dedicated solution later. Upon learning that the customer had their own sand conveying system, the team immediately adjusted the purchase list; when the customer inquired about the suitability of 100-mesh sand, the technical team dispelled the customer's concerns with the professional answer, "80-mesh is the production bottom line, 100-mesh is better."

Demand Reconstruction: Flexible Configuration Achieves Optimal Investment Solution

During the equipment selection process, both parties communicated efficiently. From the customer's initial two-shift plan being adjusted to a single-shift plan, to the mold box specifications changing from a 3.02CBM long mold box after multiple rounds of discussions, ultimately deciding to use a 3-meter long mold box with 10 mold frames and 18 mold bottoms paired with an integrated vertical and horizontal machine, every detail was quickly finalized on-site. Considering the cost, the customer pointed out that the mechanical gripper budget was too high, and the team immediately recommended a forklift-type embryo gripper as a replacement, meeting the needs while reducing costs.

This highly efficient cooperation, resulting in an order during the first visit, is not only a strong testament to Guangzhou Hengde's technical strength and service level but also demonstrates the company's strong competitiveness in the international market. In the future, Guangzhou Hengde will fully promote the project implementation, provide full-process technical support to the Albanian customer, and work together to explore the new blue ocean of the European green building materials market.

Client signing,Lightweight block equipment